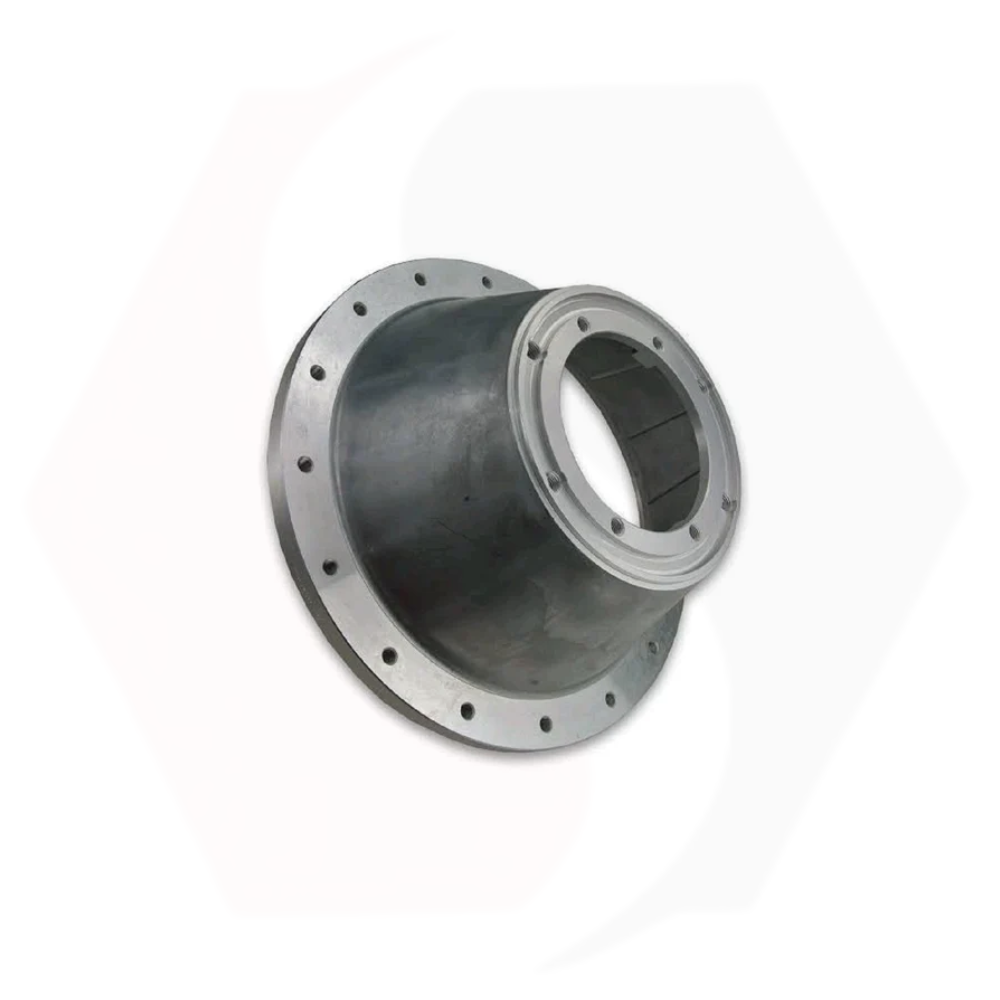

Forged Differential Case

Price 150 INR/ Piece

Forged Differential Case Specification

- Process

- Hot Forging

- Product Type

- Forged Products

- Material

- Other

- Technology

- Forging

- Application

- Other

- Weight

- 700 Grams (g)

Forged Differential Case Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001

About Forged Differential Case

A forged differential case is a critical structural component within a vehicles drive train, responsible for enclosing and supporting the internal gears that allow the wheels to rotate at different speeds essential for smooth turning and traction control. Unlike cast or machined alternatives, a forged differential case is manufactured by applying intense heat and pressure to a solid piece of steel or alloy. This forging process compresses and aligns the metals grain structure, resulting in significantly higher strength, toughness, and fatigue resistance.

Because of these superior mechanical properties, forged differential cases are widely used in high-stress environments such as heavy-duty trucks, performance vehicles, racing applications, and off-road machines. They are designed to withstand extreme torque loads, sudden shock impacts, and harsh operating conditions without cracking or deforming. The enhanced rigidity also helps maintain precise gear alignment inside the differential, improving reliability, efficiency, and overall drive train longevity.

In summary, a forged differential case offers exceptional durability, structural integrity, and performance making it a preferred choice for demanding applications where maximum strength and long-term dependability are essential.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Forged Product Category

Forged Sensor Brackets

Price 60.00 INR / Piece

Minimum Order Quantity : 5000 Pieces

Technology : Forging

Process : Hot Forging

Application : Other

Material : Other

Forged Pulley Shafts

Price 200 INR / Piece

Minimum Order Quantity : 5000 Pieces

Technology : Forging

Process : Hot Forging

Application : Other

Material : Other

Forged Crankshafts

Price 200 INR / Piece

Minimum Order Quantity : 5000 Pieces

Technology : Forging

Process : Hot Forging

Application : Other

Material : Other

Upset Forging Parts

Price 50 INR / Piece

Minimum Order Quantity : 5000 Pieces

Technology : Forging

Process : Forging

Application : Auto Parts

Material : Zinc

Send Inquiry

Send Inquiry