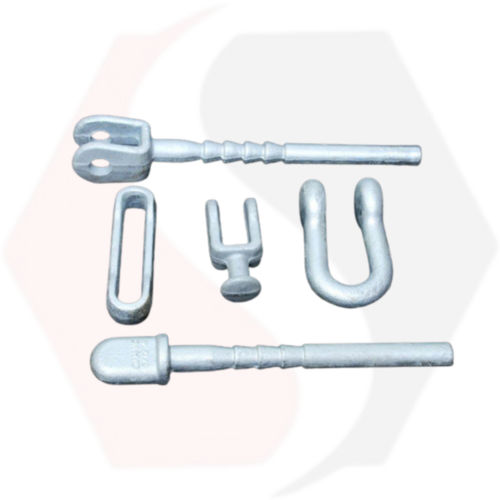

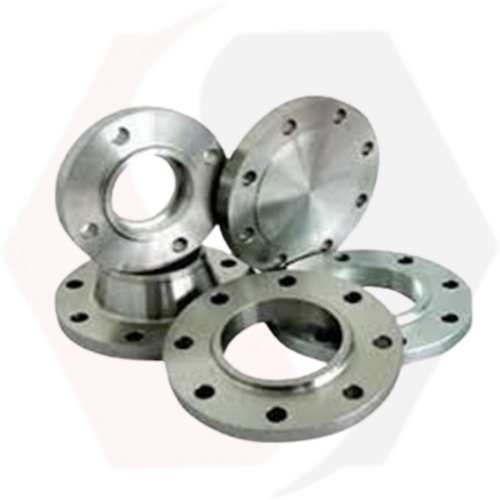

Manufacturing a premium range of Precision Components including Industrial U Bolts, Precision Forging Components, Clutch Hub, etc.

About Us

Our company, Super Auto Industries has been keeping a close watch on the ever-increasing demand for numerous industrially used items in the market and addressing them with our high-quality selection. We were founded in the year 2004, and we have since become a well-known manufacturer, supplier and wholesaler of high-quality industrial products. We have teamed up with some of the leading vendors to receive finest quality raw materials from them. Using the best resources, we manufacture the finest range of goods, such as Engine Lever Parts, Precision Forging Components, Mild Steel Elevator Bolts, Two Wheeler Clutch Component, Forged Steel Tractor Parts, MS Eye Bolts, etc. Furthermore, we ensure that all manufactured goods are carefully examined before being approved for distribution to customers.

Our Vision

The vision of our company is to be most successful and well-respected engineering company in the marketplace.

Our Mission

Our mission is to always evaluate and enhance all aspects of

our business and relations with both our internal and external

customers.

Our Core Values

The core values of our company are mentioned below:

- To have excellence in our field.

- To ensure complete satisfaction of customer by serving with the best.

- To ensure integrity and honesty when dealing with our stakeholders.

- To ensure that there is continuous improvement on our part.

- To believe in team work at all times.

- To focus on innovation for enhancing our product range comprising Precision Forging Components, Two Wheeler Clutch Component, MS Eye Bolts, Engine Lever Parts, Forged Steel Tractor Parts, etc.

Infrastructural Set-Up & Manufacturing Unit

Our infrastructure is

state-of-the-art and encompasses a fully automated production facility,

where large quantities of items are manufactured. Machines and equipment

of new technologies are placed in our infrastructural facilities. We

manufacture the highest quality items like Two Wheeler Clutch Component, Engine Lever Parts, Precision Forging Components, Forged Steel Tractor Parts, MS Eye Bolts, etc., in a precise manner using high-end equipment in our premises.

Our Warehouse

Our products are properly stored at

our warehouse, which is spread out across a large area. All of the

produced items are stored in a secure and orderly way in our warehouse.

Furthermore, we are able to supply our items immediately from our

warehouse when a customer requests them.

Why Us?

Some essential aspects that assist us in having a competitive market edge are listed below:

- We handle customers in a respectful way.

- We ensure prompt completion of all orders.

- We keep the pricing of our products affordable.

- We only deliver high-quality goods like Engine Lever Parts, Forged Steel Tractor Parts, Two Wheeler Clutch Component, MS Eye Bolts, etc.

Quality Control

Our quality control measures in various stages can be reflected with the help of the following:

- Receiving Inspection of purchased Products

- Chemical & physical testing of each batch in accordance with the control plan with the respective reports.

- Verification of raw materials against all applicable standards for purchased bright bars and other assembly spares.

- Purchased bright bars and other assembly spares are dimensionally inspected.

- In-Process Inspection

- Setting the approval of the production process in accordance with the designed control plan and the prepared drawing.

- On an hourly basis, in-process inspection is carried out according to the designed control plan with reference to the drawing.

- Separation of identification & traceability of the goods which are non-confirming during the in-process inspection stage.

- Final Inspection

- Performing a complete visual assessment of the entire lot in conformance with the detailed plan. Misfill, dent marks, bent and other visual faults are some of the most common.

- With respect to the prepared drawing, sampling dimensional inspection is carried out according to the control plan.

- 100 percent dimensional examination of important dimensions with smaller tolerance. This is carried out according to the control plan.

- During the final stage, the non-conforming goods are identified and traced separately.

- Pre-Dispatch Inspection

- Prior to delivering a batch to the customer, a pre-dispatch inspection is carried out. During this inspection, an inspection report is prepared based on the examination of the samples as per the client drawings or internal drawing.

We are accepting only bulk orders.