Forged Parts

Price 20 INR/ Piece

Forged Parts Specification

- Surface Treatment

- zinc Plating

- Process

- Hot Forging

- Hardness

- Rigid

- Product Type

- Forged Products

- Material

- Carbon Steel

- Technology

- Forging

- Application

- Other

- Weight

- 30 gram To 7 kg Grams (g)

- Color

- As Per Forge

Forged Parts Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Domestic Market

- All India

- Certifications

- ISO 9001

About Forged Parts

"Forged parts are metal components shaped through the forging process, which involves applying high pressure and heat to enhance their strength, durability, and structural integrity. These parts are essential in various industries such as automotive, aerospace, construction, and heavy machinery, offering superior performance and resistance to wear, impact, and fatigue."

Keywords:

* Forged parts

* Forged metal parts

* High-strength forged parts

* Precision forged components

* Industrial forged parts

* Custom forged parts

* Forged steel parts

* Durable forged components

* Forging manufacturer

* Automotive forged parts

* Aerospace forged parts

* Heavy-duty forged parts

* Metal forging components

* OEM forged parts

* Forged machinery parts

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in forged components Category

Forged Product

Price 25 INR / Piece

Minimum Order Quantity : 5000 Pieces

Technology : Forging

Process : Hot Forging

Product Type : Forged Products

Material : Carbon Steel

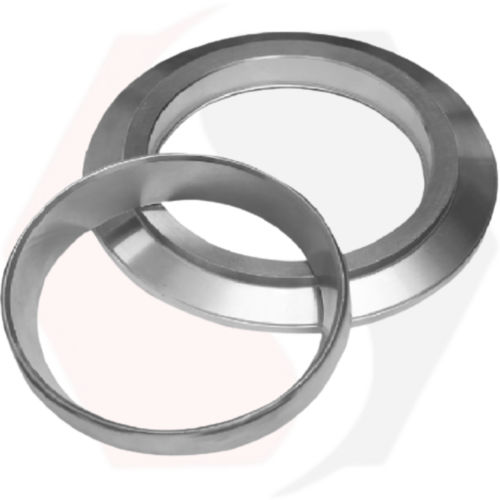

Forged Ring Product

Price 80 INR / Piece

Minimum Order Quantity : 5000 Pieces

Technology : Forging

Process : Hot Forging

Product Type : Forged Products

Material : Steel

Forged Steering Knuckle

Price 140 INR / Piece

Minimum Order Quantity : 5000 Pieces

Technology : Forging

Process : Hot Forging

Product Type : Forged Products

Material : Other

Vertical Upset Forgings

Price 25 INR / Piece

Minimum Order Quantity : 5000 Pieces

Technology : Forging

Process : Hot Forging

Product Type : Forged Products

Material : Zinc

Send Inquiry

Send Inquiry