Forged Turbine Hubs

Price 120 INR/ Piece

Forged Turbine Hubs Specification

- Process

- Hot Forging

- Material

- Other

- Application

- Other

- Color

- Black

Forged Turbine Hubs Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001

About Forged Turbine Hubs

A Forged Turbine Hub is a critical rotating component used in steam, gas, hydro, or wind turbines to connect the turbine shaft with the blades or rotor assembly. It serves as the central element that transmits torque and rotational energy from the shaft to the blades, ensuring smooth and efficient power generation.

Manufactured through a forging process, the turbine hub is formed under high pressure and temperature to achieve a refined grain structure and superior mechanical properties. This results in excellent strength, toughness, fatigue resistance, and structural integrity, which are essential for withstanding extreme operating conditions such as high rotational speeds, temperature fluctuations, and dynamic loads.

Forged turbine hubs are typically produced from high-grade alloy steels, stainless steels, or nickel-based alloys, depending on the turbine type and service environment. The forging is then subjected to heat treatment, precision machining, and non-destructive testing (NDT) to meet stringent industry specifications and performance standards.

*Key Characteristics

* High strength and fatigue resistance for rotating applications

* Excellent metallurgical integrity due to forging process

* Capable of operating under high temperature and pressure conditions

* Superior resistance to thermal and mechanical stresses

* Manufactured to tight dimensional tolerances

*Applications

* Gas turbines

* Steam turbines

* Hydro turbines

* Wind turbine rotor assemblies

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hot Forging Parts Category

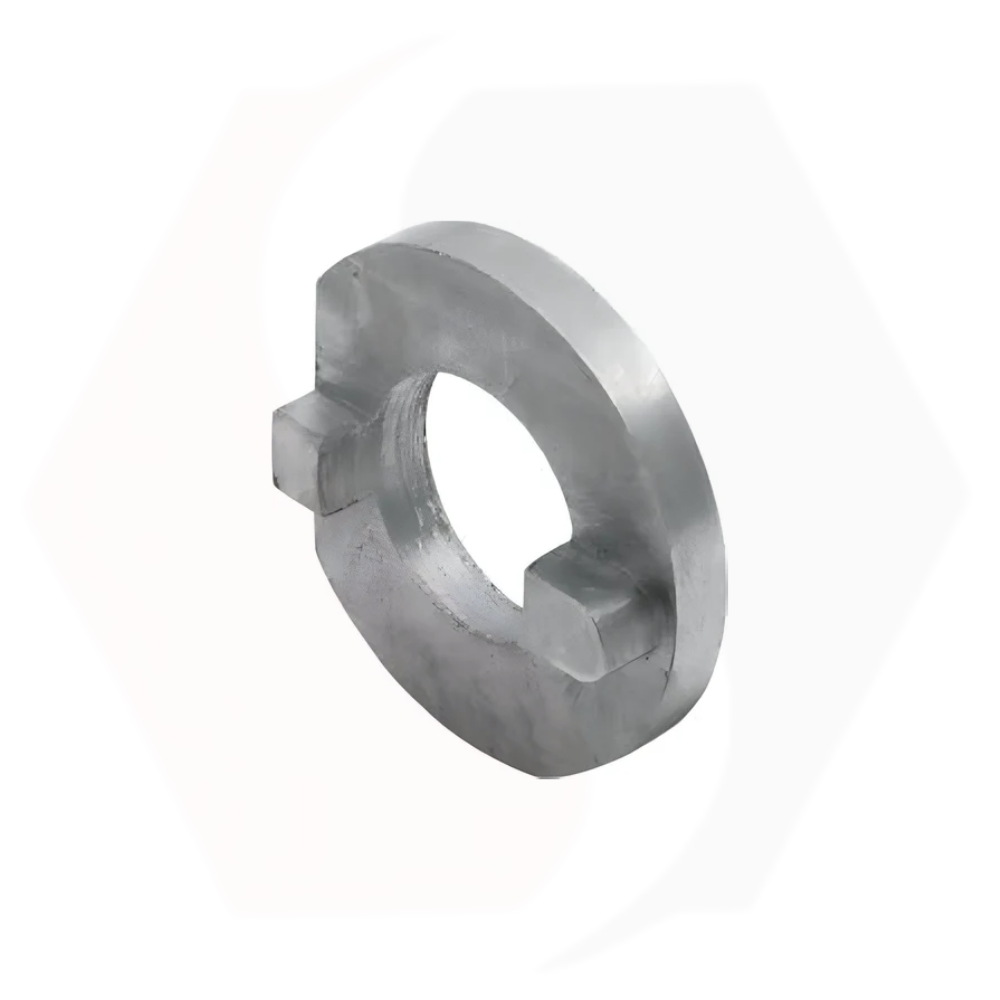

Forged Shaft Collars

Price 200.00 INR / Piece

Minimum Order Quantity : 5000 Pieces

Product Type : Forged Products

Technology : Forging

Process : Hot Forging

Application : Other

Mild Steel Hydraulic Caps

Price 45 INR / Piece

Minimum Order Quantity : 5000 Pieces

Product Type : Forged Products

Technology : Forging

Process : Hot Forging

Application : Other

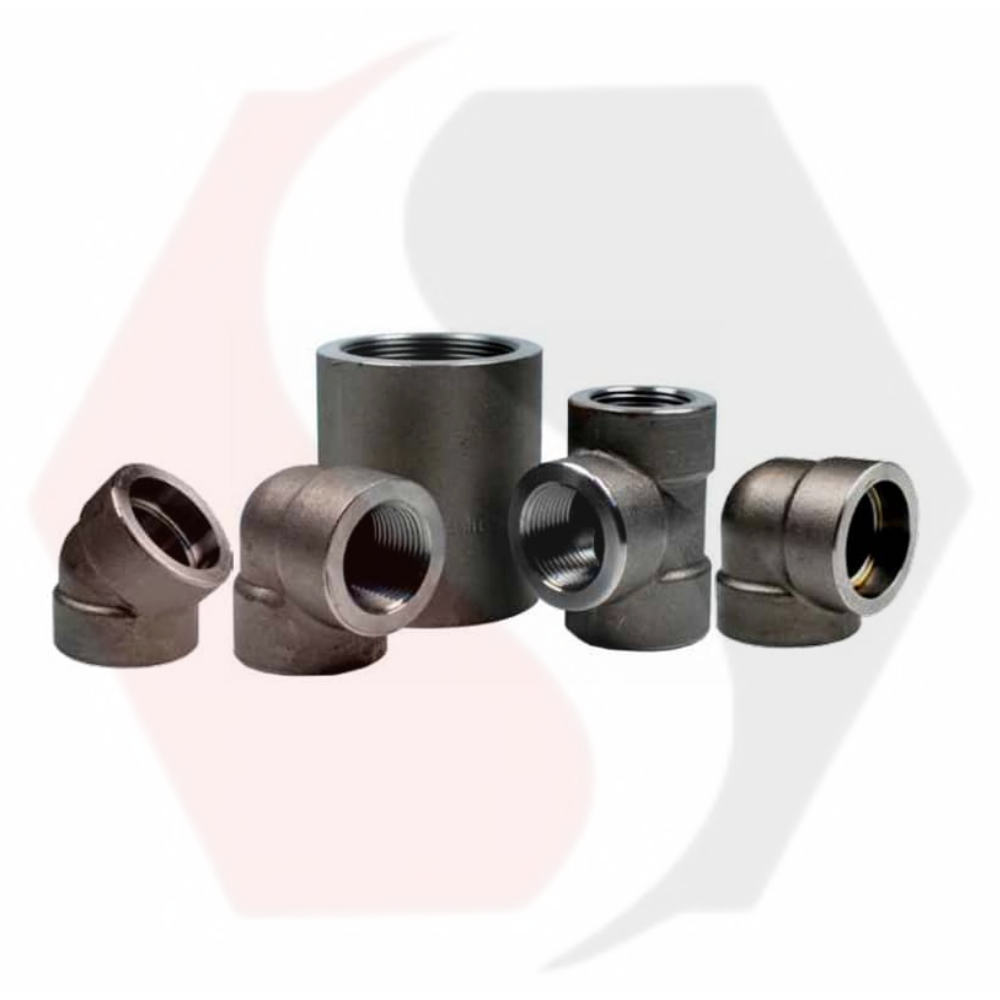

Forged Fitting Elbow

Price 120 INR / Piece

Minimum Order Quantity : 5000 Pieces

Product Type : Forged Products

Technology : Forging

Process : Hot Forging

Application : Pipe Fittings

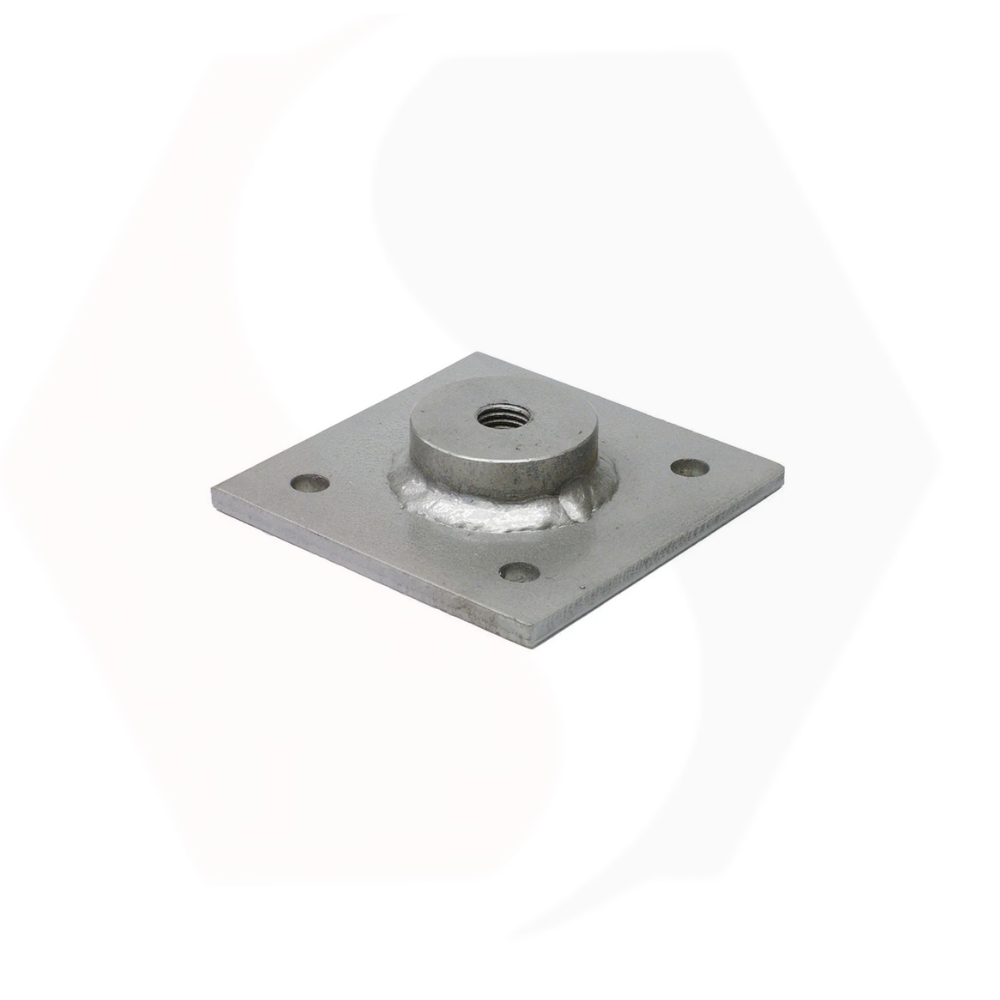

Forged Base Plate

Price 70 INR / Piece

Minimum Order Quantity : 5000 Pieces

Product Type : Forged Products

Technology : Forging

Process : Hot Forging

Application : Other

Send Inquiry

Send Inquiry