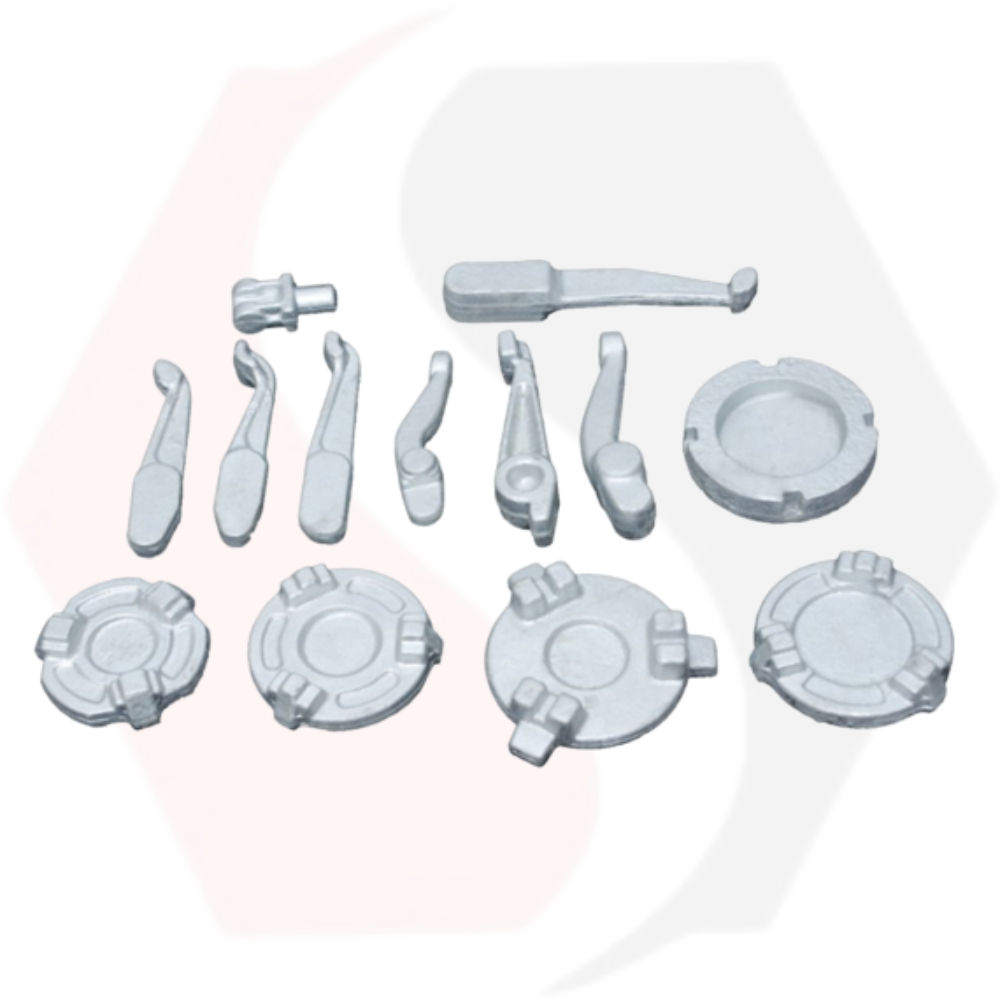

Forging Precision Component

Price 40 INR/ Piece

Forging Precision Component Specification

- Process

- Hot Forging

- Surface Treatment

- zinc Plating

- Product Type

- Forged Products

- Material

- Other

- Technology

- Forging

- Application

- Other

- Weight

- 30 gram To 7 kg Grams (g)

- Color

- As Per Forge

Forging Precision Component Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001

About Forging Precision Component

"Forging precision components are meticulously crafted metal parts produced through advanced forging techniques to achieve exact dimensions, superior strength, and excellent surface finish. These components are essential in industries such as aerospace, automotive, medical, and industrial machinery, where high accuracy and reliability are critical."

Keywords:

* Forging precision component

* Precision forged parts

* High-accuracy forged components

* Forged metal precision parts

* Custom precision forging

* Precision forging manufacturer

* Forged aerospace components

* Automotive precision forged parts

* Industrial precision forged components

* High-strength precision forged parts

* Forging with tight tolerances

* Durable precision forged components

* Precision forged machinery parts

* CNC forged precision components

* Forging process precision parts

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Forgings Category

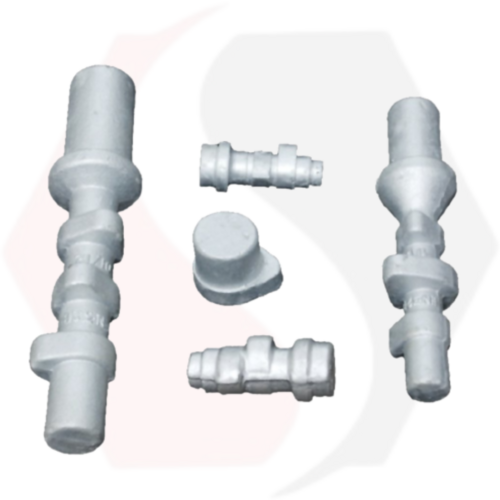

Forged Coupling Pins

Price 90 INR / Piece

Minimum Order Quantity : 5000 Pieces

Material : Zinc

Process : Hot Forging

Application : Other

Technology : Forging

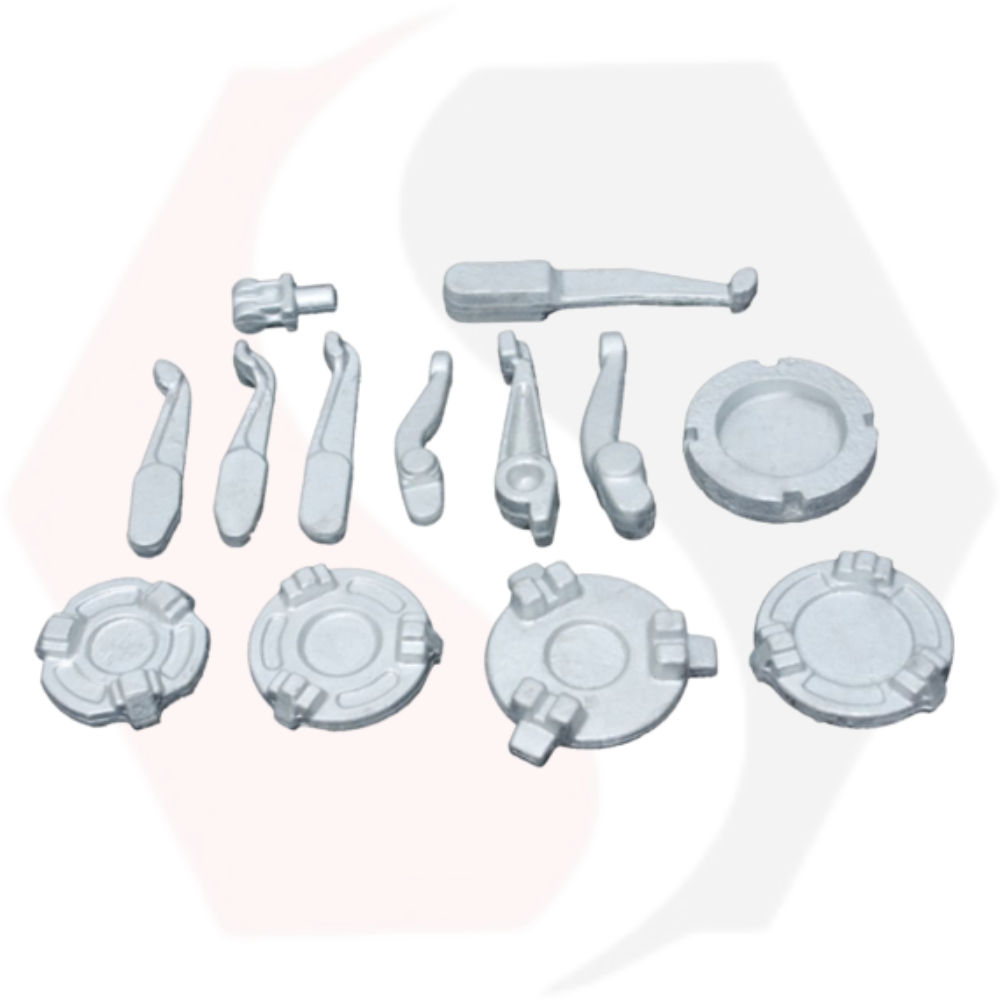

Forged Torque Arms

Price 77 INR / Piece

Minimum Order Quantity : 5000 Pieces

Material : Other

Process : Hot Forging

Application : Other

Technology : Forging

Forged Axle Yoke

Price 55 INR / Piece

Minimum Order Quantity : 5000 Pieces

Material : Other

Process : Hot Forging

Application : Other

Technology : Forging

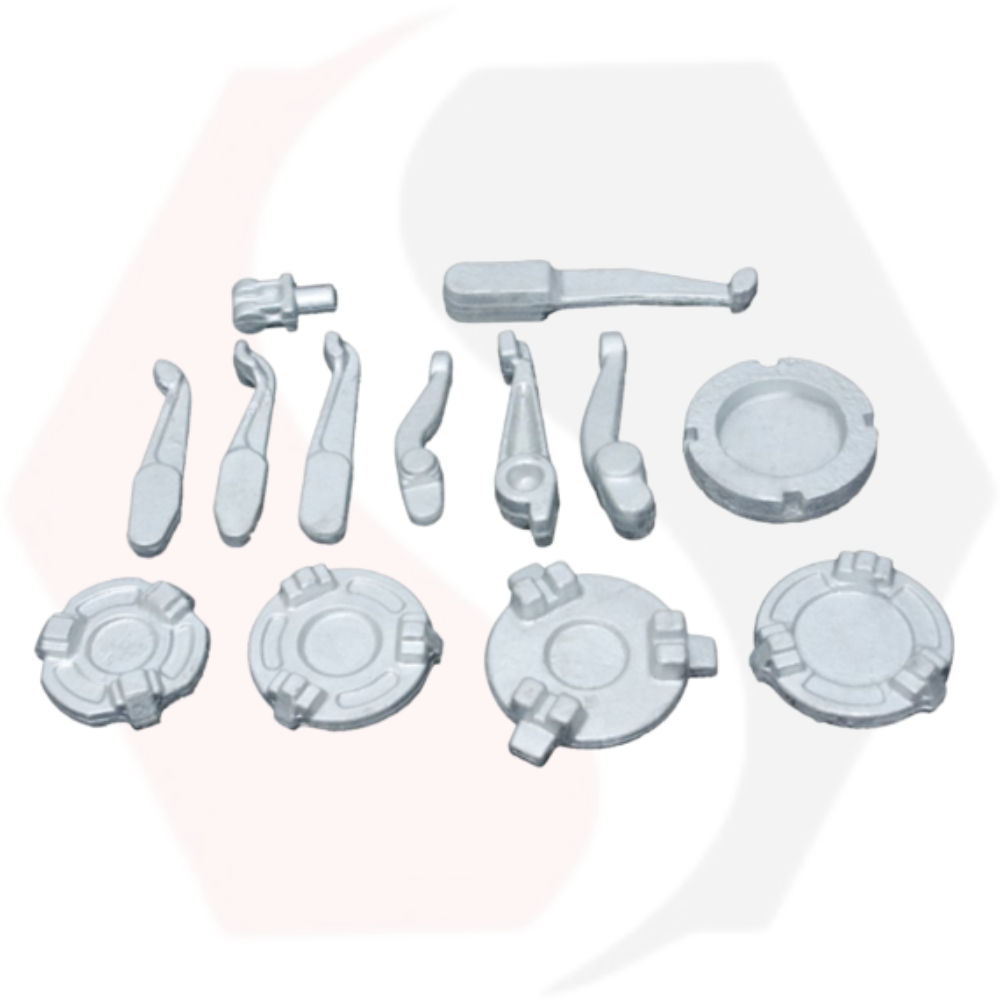

Forging Beam Clamp

Price 70 INR / Piece

Minimum Order Quantity : 5000 Pieces

Material : Other

Process : Hot Forging

Application : Other

Technology : Forging

Send Inquiry

Send Inquiry