Hot Forged Automobile Products

Price 40 INR/ Piece

Hot Forged Automobile Products Specification

- Process

- Hot Forging

- Product Type

- Forged Products

- Material

- Other

- Technology

- Forging

- Application

- Other

- Weight

- 280 gram Grams (g)

Hot Forged Automobile Products Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001

About Hot Forged Automobile Products

Hot forged automobile products are high-strength automotive components manufactured through a metal forming process in which steel or other alloys are heated to elevated temperatures and shaped under powerful compressive forces. This process refines the internal grain structure of the metal, eliminates porosity, and enhances mechanical properties such as tensile strength, toughness, fatigue resistance, and impact durability. As a result, hot forged components are ideal for applications that demand exceptional reliability and performance under heavy loads, high stress, and extreme operating conditions.

In the automotive industry, hot forging is widely used to produce critical safety and power train parts. These include crankshafts, connecting rods, camshafts, gears, axles, transmission shafts, steering knuckles, suspension arms, wheel hubs, and various engine and drive train components. Because these parts are subjected to continuous stress, vibration, torque, and temperature fluctuations, the superior structural integrity achieved through hot forging ensures long service life and consistent performance.

The hot forging process typically involves heating raw metal billets to temperatures above their re crystallization point, then shaping them using forging presses or hammers within precision dies. This controlled deformation improves the alignment of the grain flow along the shape of the component, increasing strength exactly where it is needed. After forging, components may undergo additional processes such as trimming, heat treatment, machining, and surface finishing to achieve precise dimensions and required performance standards.

Compared to casting or machining from solid stock, hot forging offers several advantages, including improved strength-to-weight ratio, reduced material waste, enhanced dimensional consistency, and better resistance to cracking and fatigue failure. These benefits make hot forged automobile products a preferred choice for manufacturers focused on safety, efficiency, and long-term durability.

Overall, hot forged automobile products play a crucial role in modern vehicles by delivering robust, high-performance components that meet stringent industry standards and support the demands of today™s engines, transmissions, and chassis systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hot Forged Part Category

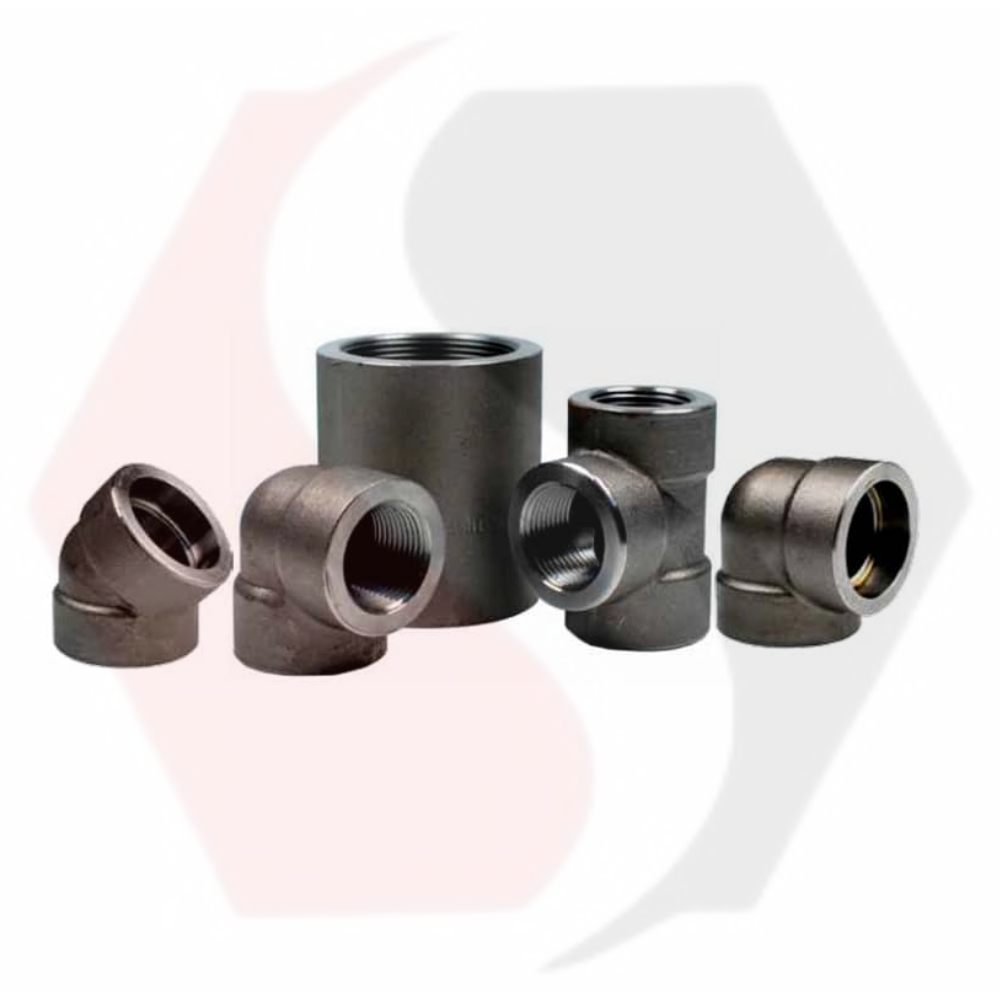

Forged Elbow

Price 70 INR / Piece

Minimum Order Quantity : 5000 Pieces

Surface Treatment : zinc Plating

Product Type : Forged Products

Color : Grey

Process : Hot Forging

Hot Forged Bushes

Price 150 INR / Piece

Minimum Order Quantity : 5000 Kilograms

Surface Treatment : Power Coating

Product Type : Forged Products

Color : Grey

Process : Forging

High-strength Precision Hot Forged Part

Price 50.00 INR / Piece

Minimum Order Quantity : 5000 Pieces

Surface Treatment : Galvanized, Mill Finish

Product Type : Forged Products

Color : Silver

Process : Forging

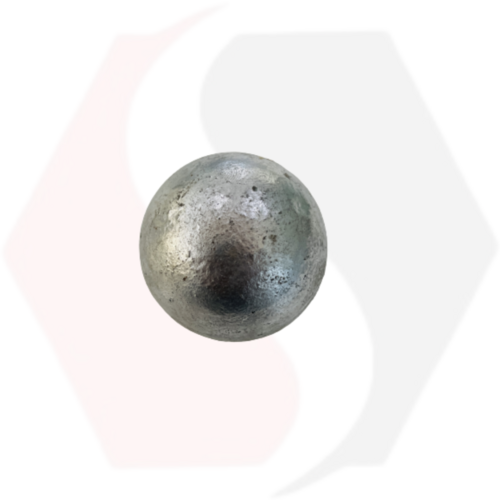

MS Hot Foged Ball

Price 25 INR / Piece

Minimum Order Quantity : 5000 Pieces

Surface Treatment : zinc Plating, Mill Finish

Product Type : Forged Products

Color : as per forge

Process : Hot Forging

Send Inquiry

Send Inquiry