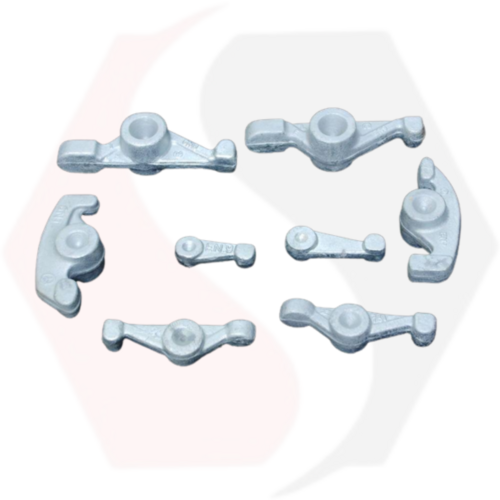

Mild Steel Forged

Price 21 INR/ Piece

Mild Steel Forged Specification

- Surface Treatment

- zinc Plating

- Process

- Hot forging

- Hardness

- Rigid

- Product Type

- Forged Products

- Material

- Carbon Steel

- Technology

- Forging

- Application

- Other

- Weight

- 30 gram To 7 kg Kilograms (kg)

- Color

- As Per Forge

Mild Steel Forged Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001

About Mild Steel Forged

"Mild steel forged products are components made by shaping mild steel through the forging process, enhancing their strength, toughness, and durability. These forged mild steel parts are widely used in construction, automotive, machinery, and industrial applications where reliable performance and structural integrity are essential."

keywords:

* Mild steel forged

* Forged mild steel parts

* Mild steel forging

* Forged MS components

* Mild steel forged products

* Forged steel parts

* Heavy-duty mild steel forging

* Industrial mild steel forged parts

* Custom forged mild steel

* Mild steel forged components manufacturer

* Durable forged mild steel

* Structural mild steel forged parts

* Precision forged mild steel

* Mild steel forging process

* Forged metal mild steel parts

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MS Forged Component Category

mild Steel Forgings

Price 200 INR / Piece

Minimum Order Quantity : 5000 Pieces

Process : Hot Forging

Product Type : Forged Products

Material : Other

Technology : Forging

Forged Suspension Parts

Price 100 INR / Piece

Minimum Order Quantity : 5000 Pieces

Process : Hot Forging

Product Type : Forged Products

Material : Other

Technology : Forging

MS Forged Component

Price 45 INR / Piece

Minimum Order Quantity : 5000 Pieces

Process : Forging

Product Type : Forged Products

Material : Steel

Technology : Forging

MS Forged Auto Parts

Price 30 INR / Piece

Minimum Order Quantity : 5000 Pieces

Process : Forging

Product Type : Forged Products

Material : Other , Mild Steel

Technology : Forging

Send Inquiry

Send Inquiry