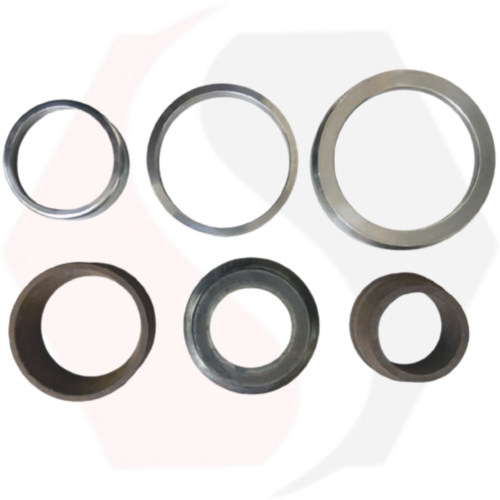

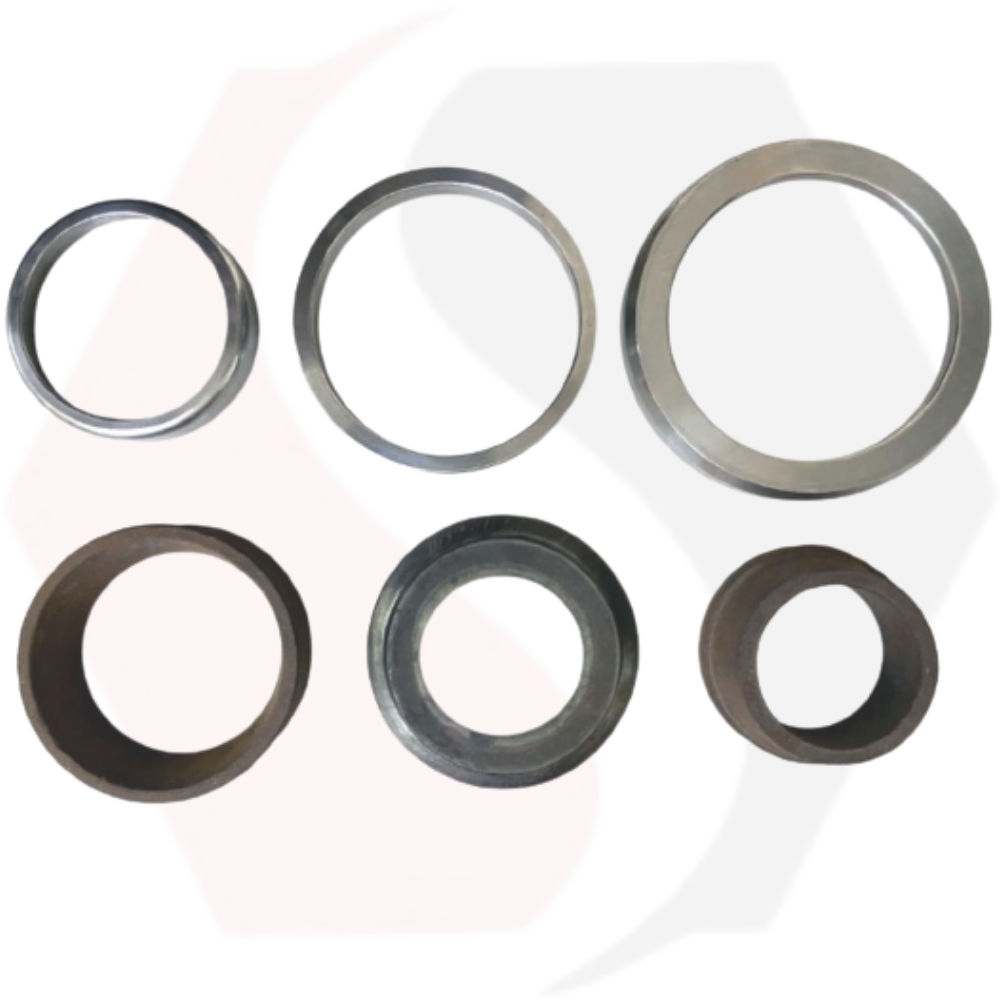

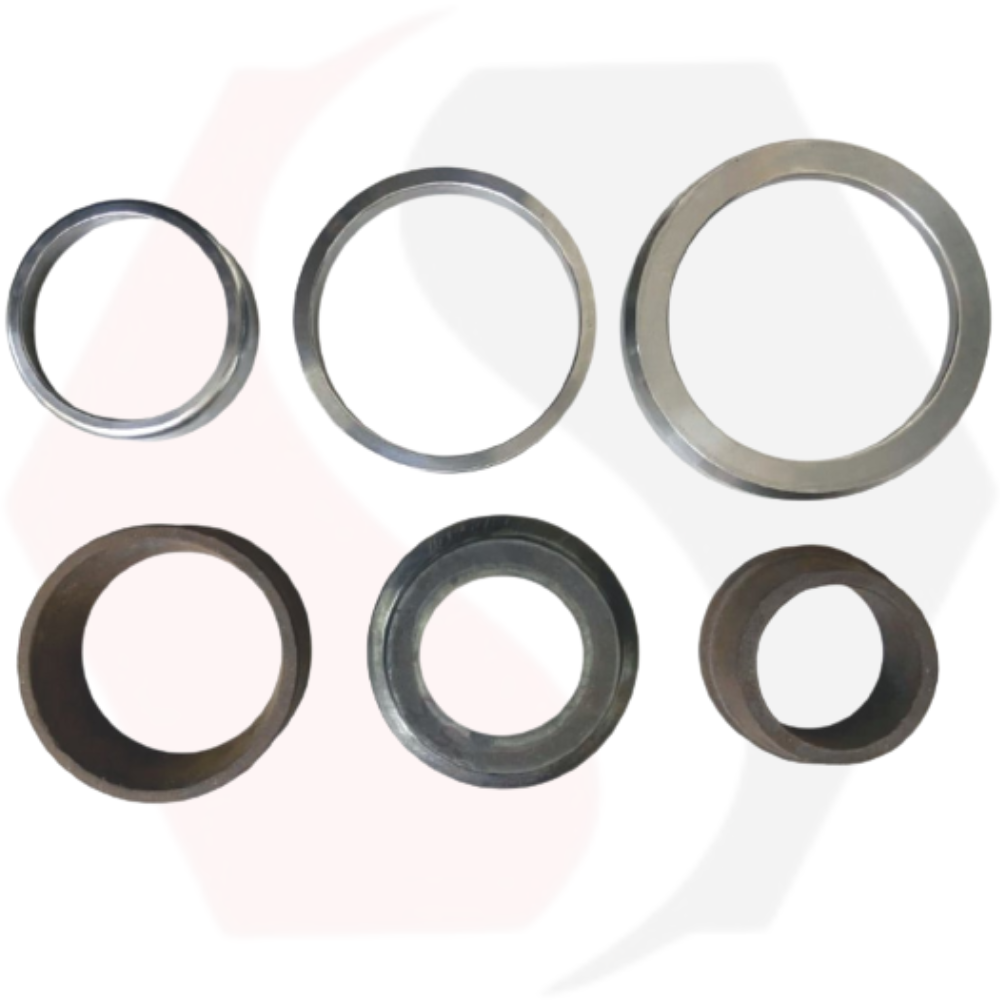

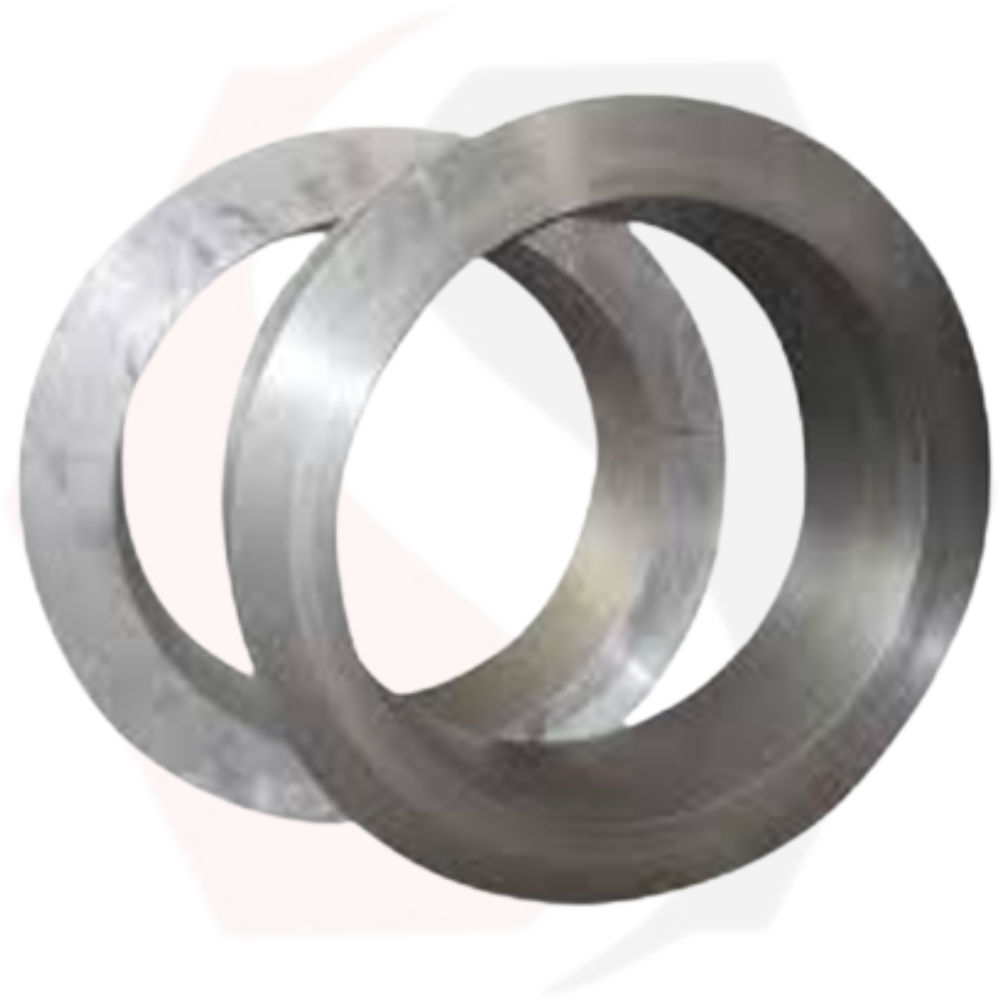

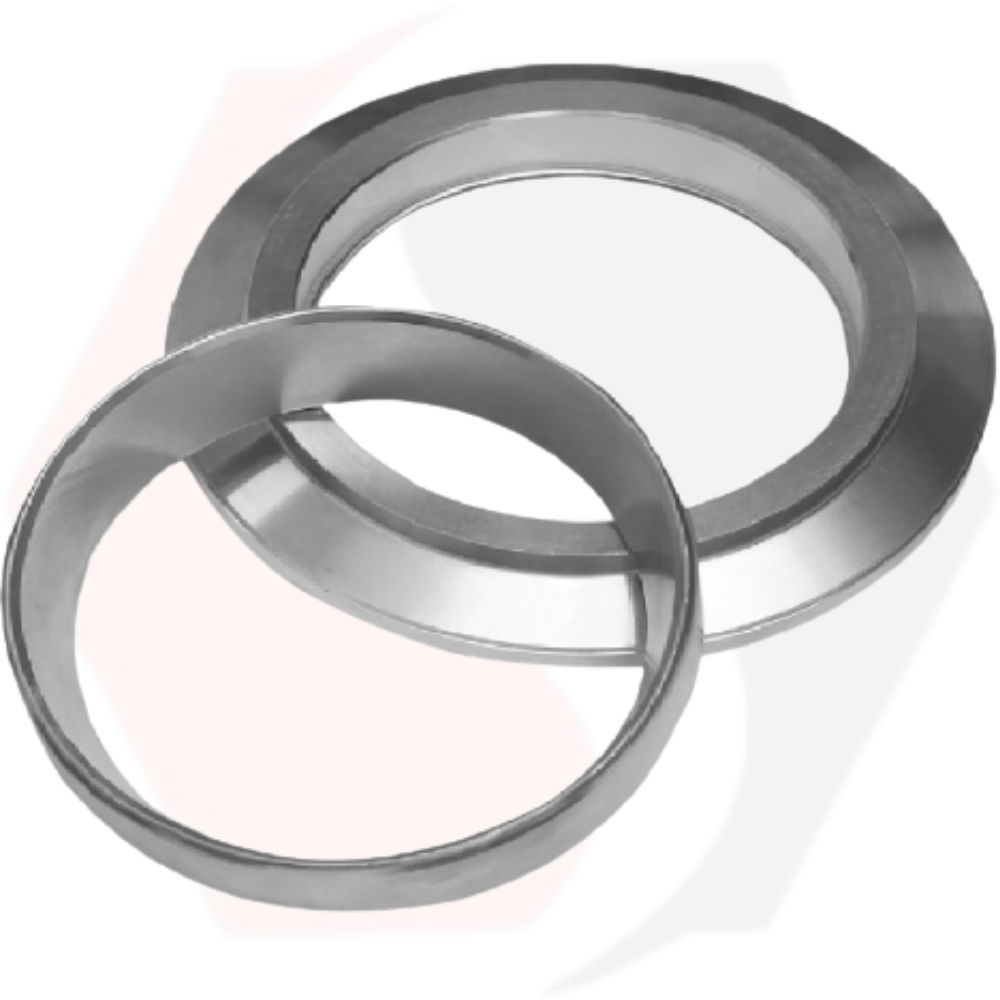

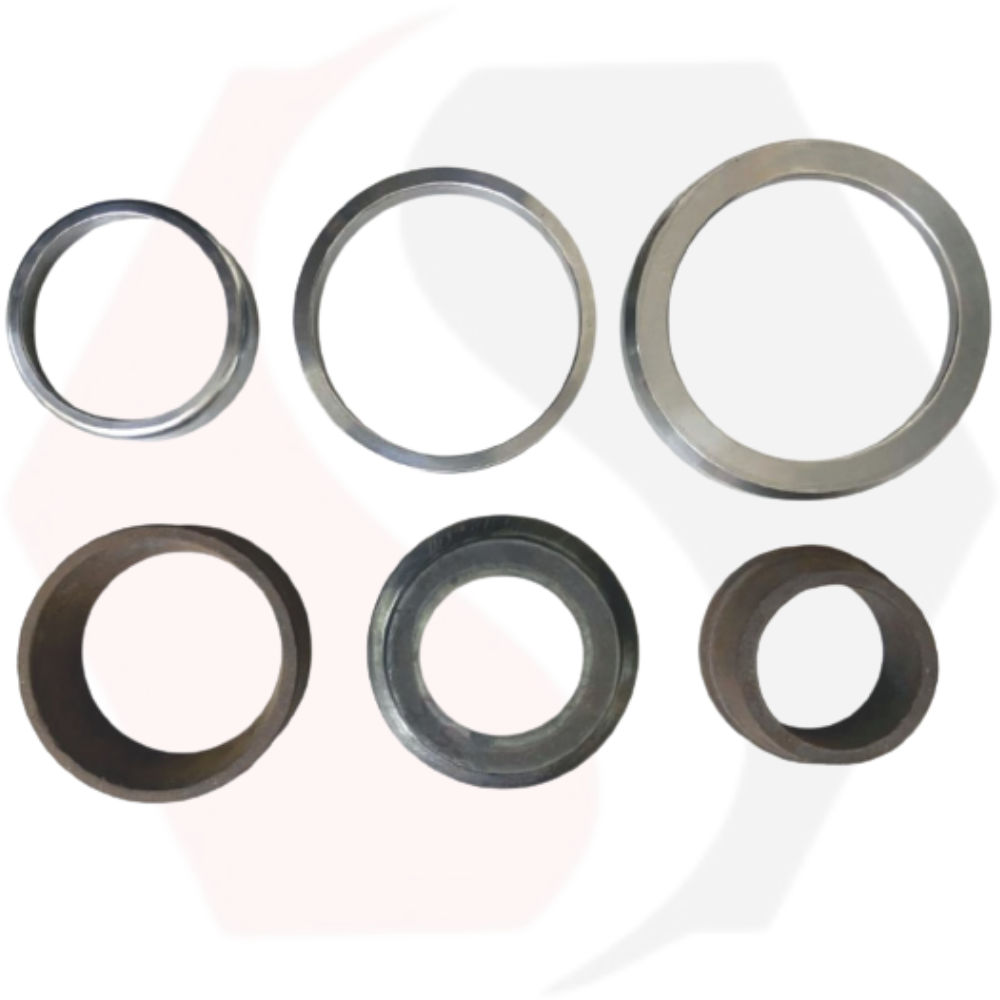

Ms Forged Ring

Price 80 INR/ Piece

Ms Forged Ring Specification

- Process

- Forging

- Hardness

- Rigid

- Surface Treatment

- As Per Requirement

- Product Type

- Forged Products

- Material

- Steel

- Technology

- Hot Forging

- Application

- Industrial Machinery & Equipment

- Dimension (L*W*H)

- Custom as per order

- Weight

- 30 gram To 7 kg Kilograms (kg)

- Color

- As Per Forge

Ms Forged Ring Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Domestic Market

- All India

- Certifications

- ISO 9001

About Ms Forged Ring

"MS Forged Rings are durable and high-strength rings made from mild steel (MS) through the forging process. These rings offer enhanced mechanical properties and are widely used in machinery, construction, automotive, and industrial applications where toughness and reliability are essential."

Keywords:

* MS forged ring

* Mild steel forged ring

* Forged mild steel ring

* Forged MS rings

* Mild steel forging

* Forged metal rings

* Heavy-duty MS forged rings

* Industrial forged rings

* Custom forged MS rings

* Forging mild steel components

* Durable forged rings

* MS ring manufacturer

* Forged steel rings

* Forged rings for machinery

* Forged rings for construction

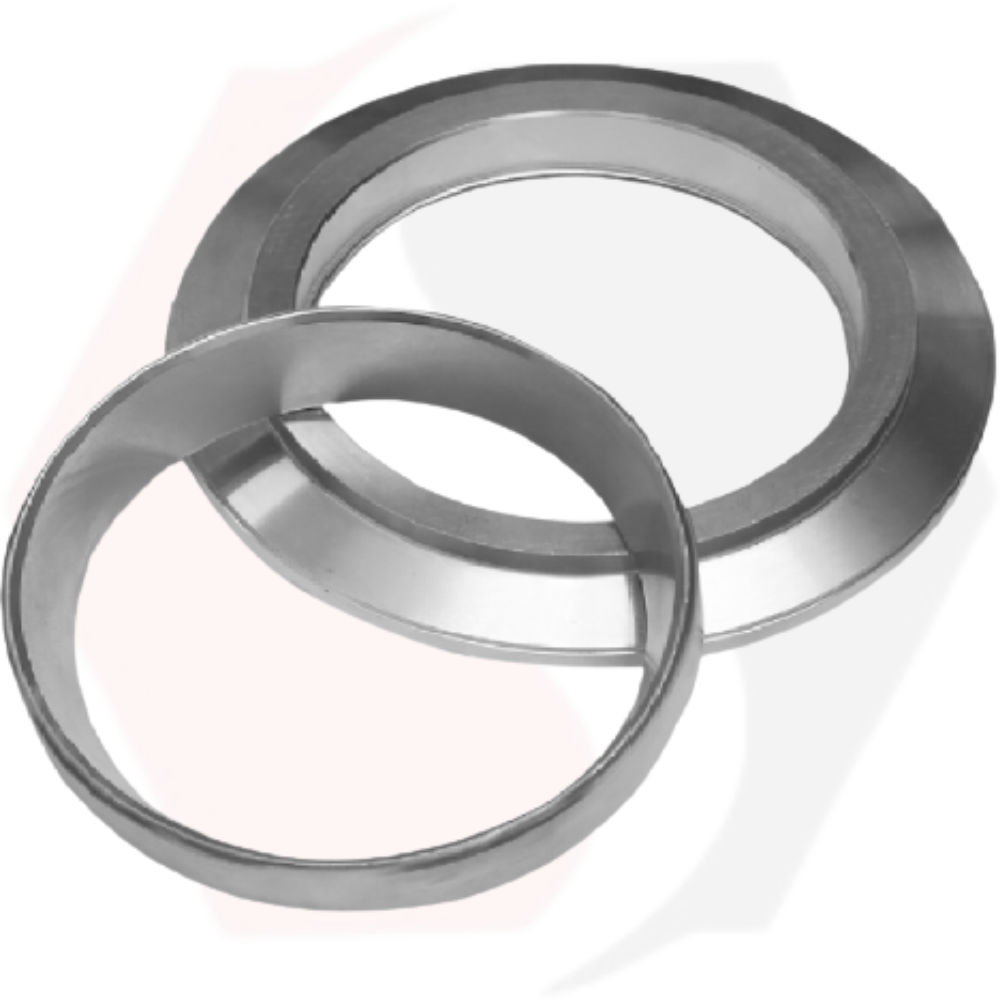

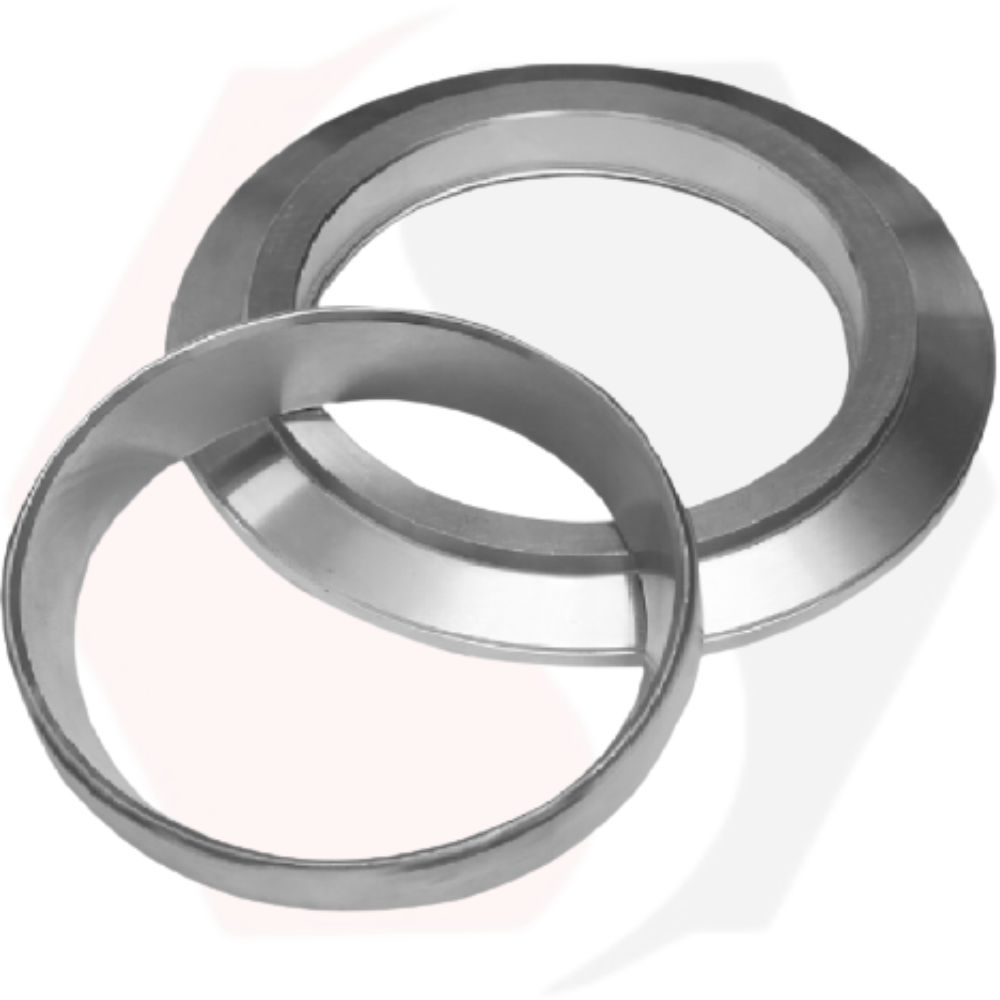

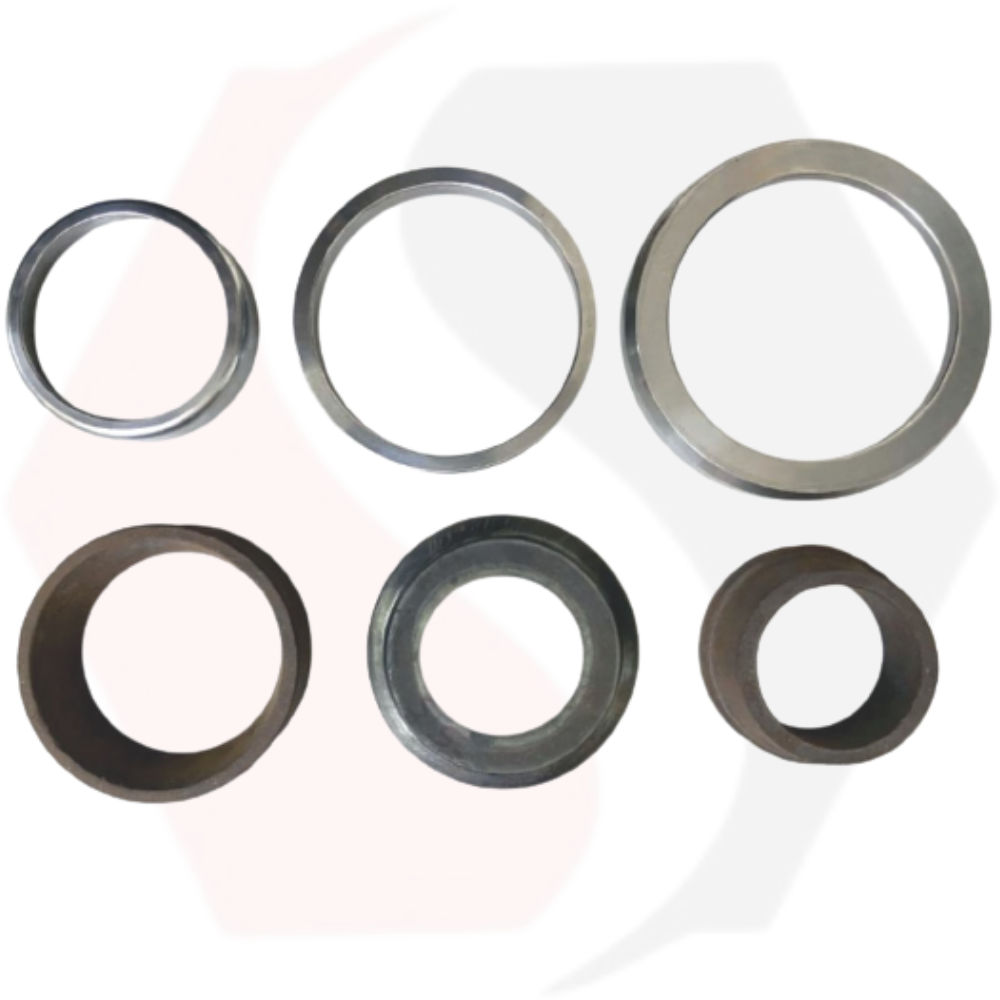

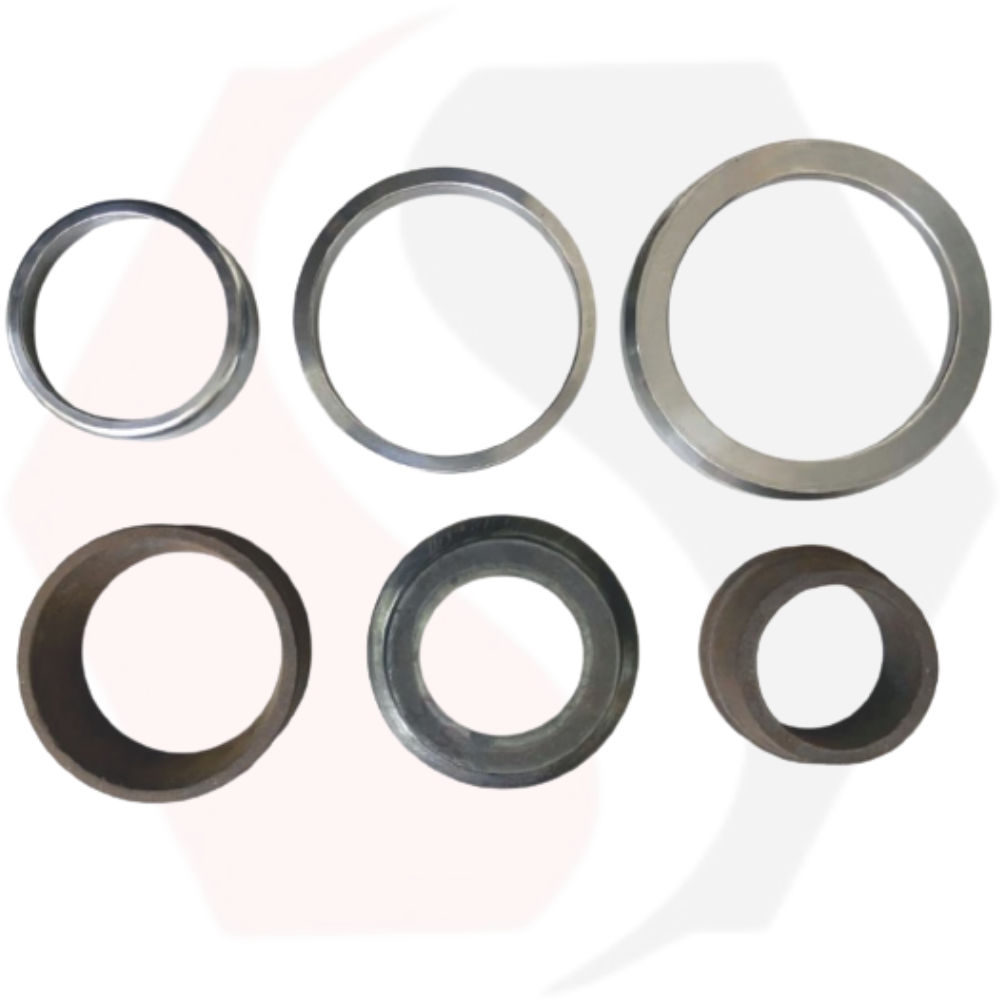

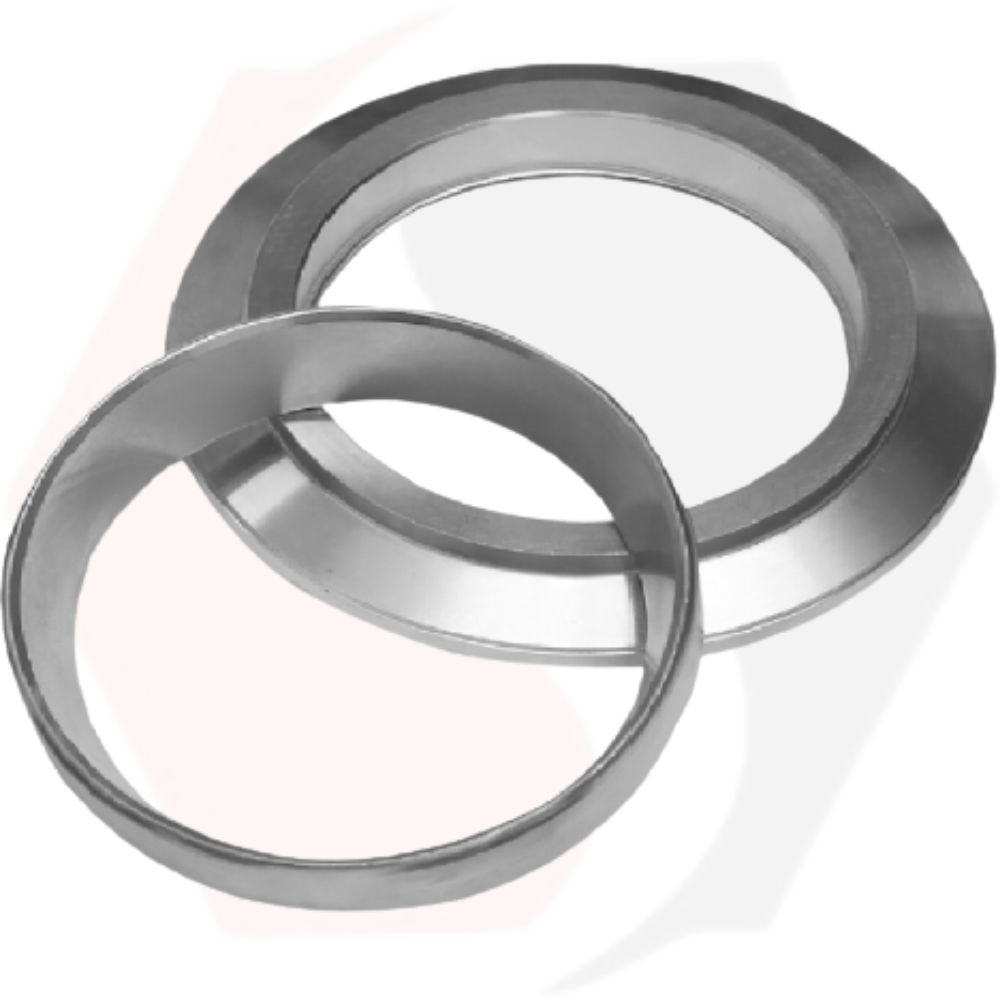

Precision Forging for Industrial Applications

Our forged rings are engineered to meet stringent industry standards, ensuring reliability in demanding environments. Each ring is crafted using hot forging technology, delivering superior mechanical properties and precise dimensional accuracy. Customization options in grade, finish, and dimensions are available, making them ideal for applications in heavy fabrication, construction, and gear manufacturing.

Material Grade and Standards Compliance

We offer MS Forged Rings in multiple grades including MS, EN8, EN9, and EN19, ensuring you receive the right material for your needs. Every ring is manufactured as per relevant industry standards such as IS, BS, ASTM, or DIN. This attention to detail guarantees compatibility and performance in your unique application.

FAQs of Ms Forged Ring:

Q: How are MS Forged Rings manufactured?

A: MS Forged Rings are produced using the hot forging process, which involves heating steel to a specific temperature and then shaping it under high pressure. This process enhances the mechanical strength and ensures that the rings meet close tolerance as per the customers drawing.Q: What applications are MS Forged Rings suitable for?

A: These forged rings are ideal for heavy fabrication, construction, gear manufacturing, flanges, and other industrial machinery and equipment applications, thanks to their durability and custom sizing options.Q: When should I choose a specific material grade such as EN8, EN9, or EN19?

A: Material grade selection depends on the mechanical properties required for your application. EN8, EN9, and EN19 provide varying levels of strength and hardness, making them suitable for different industrial environments. Our team can guide you to the appropriate grade based on your needs.Q: Where are these forged rings typically supplied from?

A: These rings are manufactured in India and supplied domestically and internationally by a reliable network of manufacturers, suppliers, and wholesalers.Q: What is the available range for outer and inner diameters of the rings?

A: Both the outer and inner diameters of the rings can be customized as per customer specifications, providing flexibility to fit a wide array of industrial applications.Q: What surface treatments and finishes can be provided with these rings?

A: We offer various surface treatments and finishes, like black, self, or machined surfaces, tailored as per customer requirements to enhance durability and corrosion resistance.Q: What are the benefits of choosing your MS Forged Rings?

A: Our MS Forged Rings offer high rigidity, close dimensional tolerance, and material versatility. Customization, compliance with top standards, and robust packaging options ensure reliable performance and safe delivery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Forged Rolled Ring Category

Forged Rolled Ring

Price 40 INR / Piece

Minimum Order Quantity : 5000 Pieces

Material : Steel

Product Type : Forged Products

Color : Silver

Process : forging

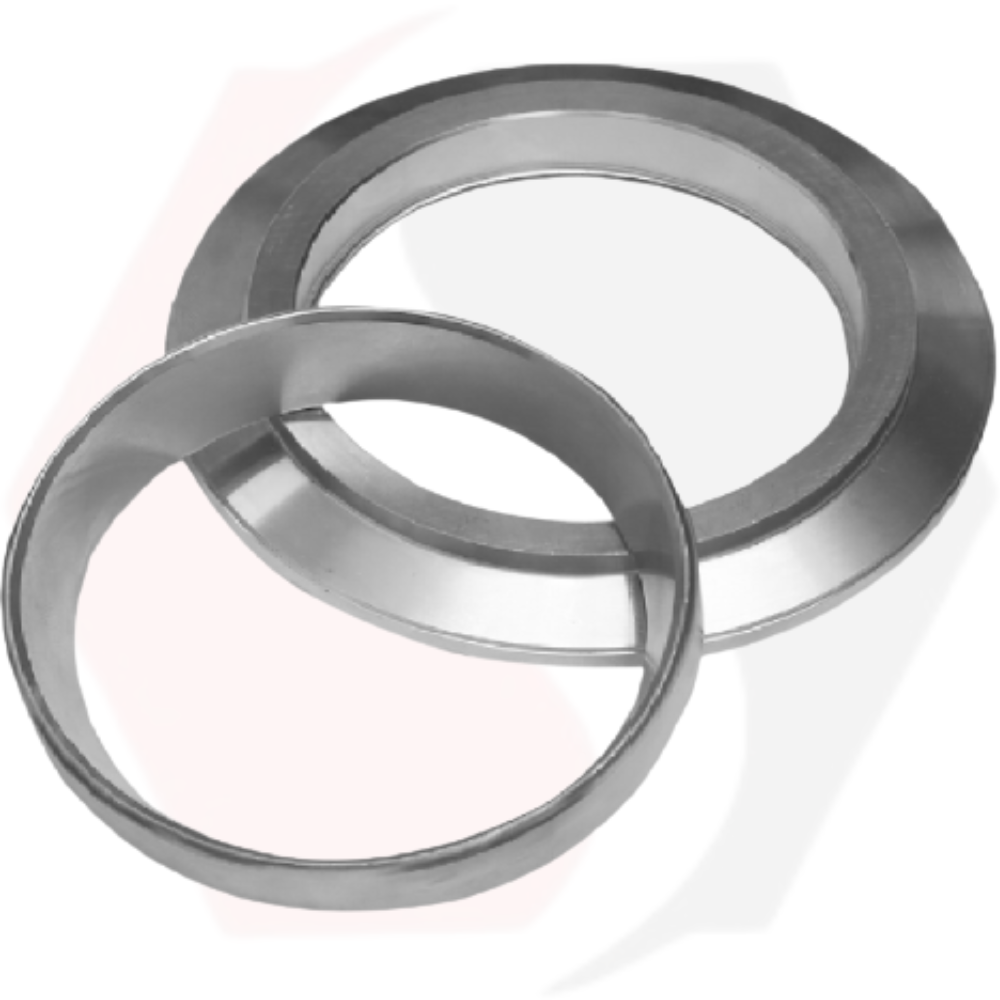

Mild Steel Round Forged Ring

Price 120 INR / Piece

Minimum Order Quantity : 5000 Pieces

Material : Zinc

Product Type : Forged Products

Color : Grey

Process : Forging

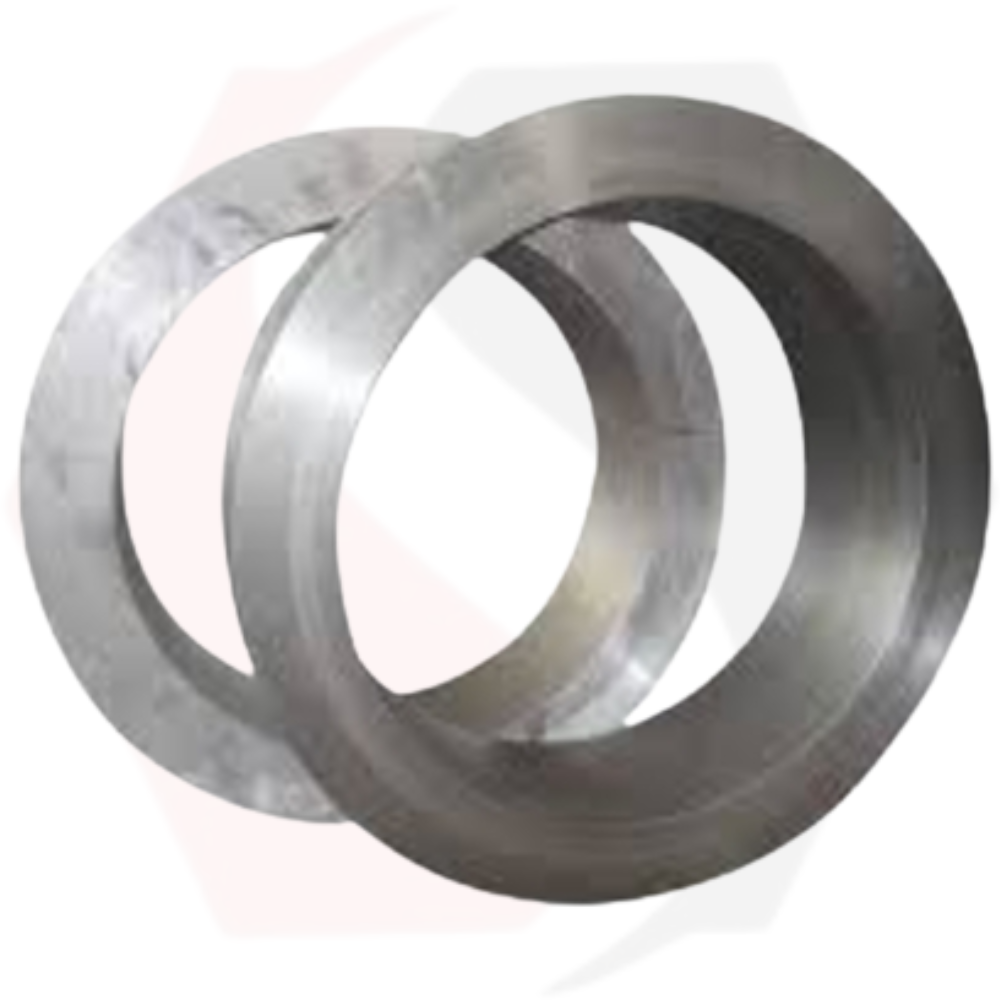

Forged & Hot Rolled Rings

Price 90 INR / Piece

Minimum Order Quantity : 5000 Pieces

Material : Zinc

Product Type : Forged Products

Color : Silver

Process : Hot Forging

Send Inquiry

Send Inquiry