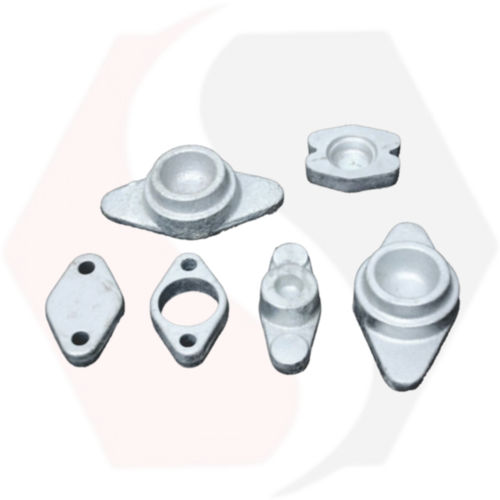

Press Forging Parts

Price 45 INR/ Piece

Press Forging Parts Specification

- Hardness

- 55-60 HRC

- Process

- Forging

- Product Type

- Forged Products

- Material

- Zinc

- Technology

- Forging

- Application

- Automotive, Machinery, Industrial Equipment

- Color

- Silver

- Standard

- ISO, DIN, ASTM

- Packaging Type

- Wooden box, Carton

- OEM Service

- Accepted

- Tolerance

- ±0.02 mm

- Grade

- High-strength zinc alloy

- Shape

- Custom, as per requirement

- Production Capacity

- Customized, based on customer needs

- Finish

- Smooth, corrosion-resistant

Press Forging Parts Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001

About Press Forging Parts

Press Forging Parts are metal components shaped using gradual, high-pressure force in a press forging machine, resulting in precise, high-strength parts used in automotive, industrial, and heavy machinery applications.

keywords

-

-

Press forging parts

-

Closed-die press forging

-

Open-die press forging

-

Precision forged components

-

Forged automotive parts

-

Industrial press forgings

-

Custom forged metal parts

-

Hydraulic press forged parts

-

Mechanical press forging

-

High-strength forging parts

-

Forged machine components

-

Metal press forging

-

Forged structural parts

-

Heat-treated forging parts

-

Press-forged steel components

-

High-precision forgings

-

Large forging parts

-

OEM forged components

-

Forging manufacturer

-

Forging supplier

Superior Quality and Customization

Each press forging part is crafted using advanced zinc-forging technology, guaranteeing high tensile strength and remarkable durability. With tolerance precision up to 0.02 mm and customizable dimensions, our products seamlessly fit your projects requirements. OEM service allows clients to request bespoke shapes and finishes, ensuring optimal integration with diverse industrial applications.

Stringent Standards and Reliable Performance

We strictly adhere to global standards, including ISO, DIN, and ASTM, ensuring every product surpasses industry benchmarks. The parts are thoroughly tested for hardness (55-60 HRC) and corrosion resistance, delivering steadfast performance even in challenging environments. The polished or zinc-plated finish enhances longevity, making our forging parts a dependable choice for long-term operations.

FAQs of Press Forging Parts:

Q: How are your press forging parts customized to meet specific client requirements?

A: We utilize customer-provided drawings and specifications to manufacture parts in custom shapes, sizes, and weights. You can specify the exact dimensions (L*W*H), finishes, and performance parameters needed for your application.Q: What benefits does the high-strength zinc alloy offer in your forging parts?

A: High-strength zinc alloy delivers excellent mechanical properties, including superior durability and resistance to wear and corrosion, making our parts ideal for demanding industrial, machinery, and automotive uses.Q: When is it recommended to choose corrosion-resistant, polished or zinc-plated finishes?

A: Corrosion-resistant, polished or zinc-plated finishes are highly recommended for components exposed to harsh environmental conditions or requiring an aesthetic, smooth surfaceespecially in machinery and industrial setups where longevity is critical.Q: Where do you supply and export these custom press forging parts?

A: We are based in India and supply these components both domestically and internationally, catering to manufacturers, suppliers, and wholesalers across various industries worldwide.Q: What is the typical process involved in manufacturing your forging parts?

A: Our process involves precision forging of zinc alloy, strict adherence to ISO/DIN/ASTM standards, detailed surface treatments, and thorough inspection to meet tolerance and hardness specifications. The final parts are securely packaged and delivered as per your requirements.Q: How can these forging parts be used across different industrial sectors?

A: These parts are primarily used in automotive, machinery, and industrial equipment sectors due to their high strength, precision, and resistance to corrosion. Their customizability allows seamless adaptation to various functional roles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Forged Automotive Component Category

Forged Automotive Component

Price 15.00 INR / Piece

Minimum Order Quantity : 5000 Pieces

Product Type : Forged Products

Color : Silver

Technology : Forging

Material : Steel

Forged Pipe U Clamp

Price 50 INR / Piece

Minimum Order Quantity : 5000 Pieces

Product Type : Forged Products

Color : Silver

Technology : Forging

Material : Zinc

Forged Rotor Hubs

Price 100 INR / Piece

Minimum Order Quantity : 5000 Pieces

Product Type : Forged Products

Color : Black

Technology : Forging

Material : Other

Automotive Forged Parts

Price 35 INR / Piece

Minimum Order Quantity : 5000 Pieces

Product Type : Forged Products

Color : As Per Forge

Material : Carbon Steel

Send Inquiry

Send Inquiry