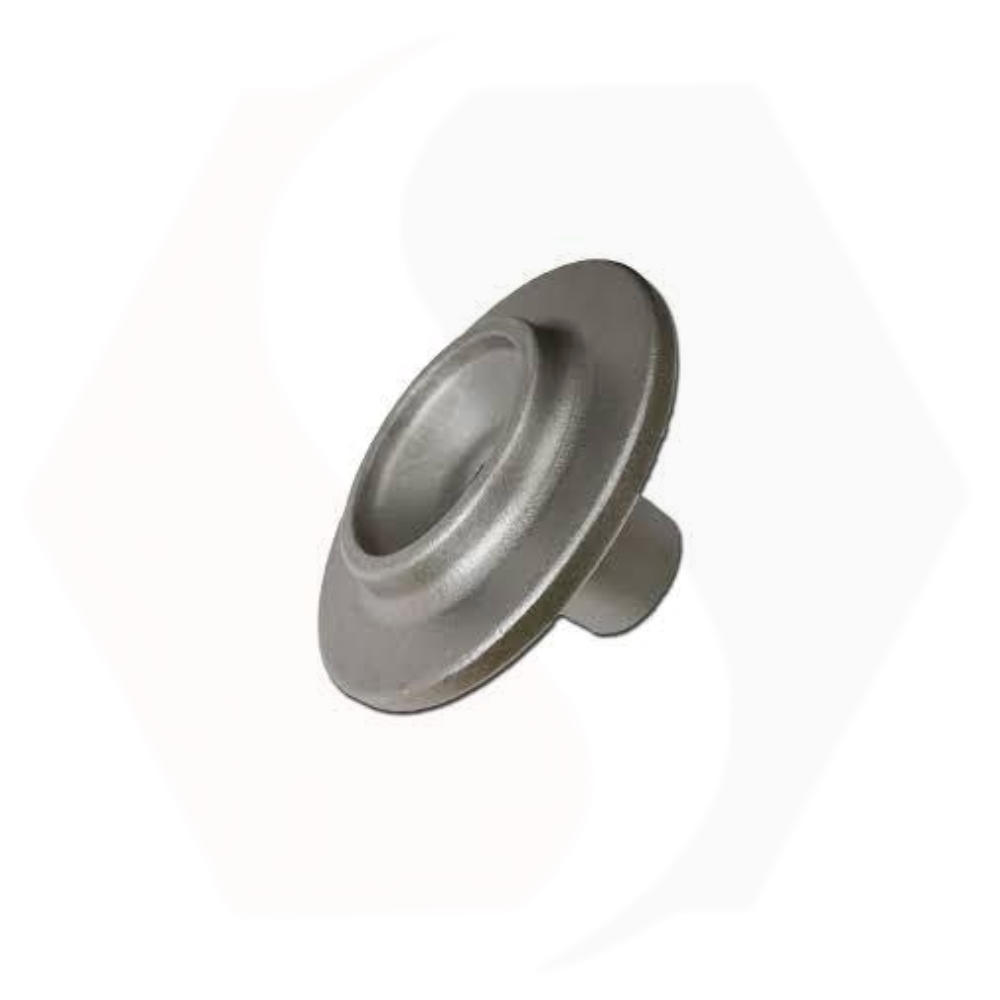

Forged Gear Hubs

Price 90 INR/ Piece

Forged Gear Hubs Specification

- Process

- Hot Forging

- Surface Treatment

- zinc Plating

- Product Type

- Forged Products

- Material

- Zinc

- Technology

- Forging

- Application

- Auto Parts

- Weight

- 400 Grams (g)

Forged Gear Hubs Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001

About Forged Gear Hubs

Forged gear hubs are heavy-duty mechanical components designed to connect and support gears, shafts, or rotating assemblies while efficiently transmitting torque and load. They are manufactured using a forging process in which high-quality metal commonly carbon steel, alloy steel, or stainless steel is heated and shaped under extreme pressure. This process refines the metals internal grain structure, resulting in a component with superior strength, toughness, and resistance to fatigue compared to cast or machined hubs.

These hubs are widely used in automotive, industrial, agricultural, mining, construction, and power-transmission applications where reliability and durability are critical. Forged gear hubs are capable of withstanding high rotational speeds, heavy radial and axial loads, and repeated stress cycles without deformation or failure. Their enhanced mechanical properties make them ideal for demanding environments and long service life.

Forged gear hubs can be produced in a wide range of sizes, shapes, and configurations to meet specific application requirements. They may feature splines, keyways, flanges, bores, or customized profiles and are often further precision-machined and heat-treated to achieve exact tolerances and performance characteristics. Surface treatments or coatings may also be applied to improve wear resistance and corrosion protection.

Overall, forged gear hubs offer a combination of high structural integrity, precise dimensional accuracy, and long-term performance, making them a preferred choice for critical torque-transmission and load-bearing systems where safety, efficiency, and durability are essential.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Forging Part Category

MS Round Forging Manufacturer

Price 150 INR / Piece

Minimum Order Quantity : 5000 Pieces

Product Type : Forged Products

Process : Hot Forging

Technology : Forging

Application : Other

Forged Yoke

Price 90.00 INR / Piece

Minimum Order Quantity : 5000 Pieces

Product Type : Forged Products

Process : Hot Forging

Technology : Forging

Application : Auto Parts

Precision Forging Components

Price 10 INR / Piece

Minimum Order Quantity : 5000 Pieces

Product Type : Forged Products

Process : Forging

Technology : Forging

Application : Auto Parts

Forged Wear Parts

Price 120.00 INR / Piece

Minimum Order Quantity : 5000 Pieces

Product Type : Forged Products

Process : Hot Forging

Technology : Forging

Application : Other

Send Inquiry

Send Inquiry