Heavy Steel Forging

Price 40 INR/ Piece

Heavy Steel Forging Specification

- Process

- Hot Forging

- Product Type

- Forged Products

- Material

- Zinc

- Technology

- Forging

- Application

- Auto Parts

- Color

- Silver

Heavy Steel Forging Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001

About Heavy Steel Forging

involves the shaping of large steel components under extreme pressure using hydraulic or mechanical presses. This process enhances the internal grain structure, increasing the strength, durability, and fatigue resistance of the finished parts. Ideal for critical applications in industries such as aerospace, oil & gas, power generation, shipbuilding, mining, and heavy machinery.

-

-

Materials: Mild steel, alloy steel

-

Processes: closed-die forging, press forging Hammer Forging

-

Product Range: Shafts, rings, flanges, blocks, arms, custom forging

-

Sizes: Custom large-diameter and high-weight parts

-

Certifications: ISO

Keywords:

-

-

HCustom steel forgings

-

Large forged steel parts

-

Industrial forging services

-

Open-die steel forging

-

Closed-die forging

-

Forged steel components

-

High-strength steel forgings

-

Steel shaft forging

-

Forged flanges and rings

-

Power generation forgings

-

Oil and gas forgings

-

Forging manufacturer

-

Heavy-duty metal forging

-

Steel forging for heavy industry

High-Quality Materials and Advanced Processes

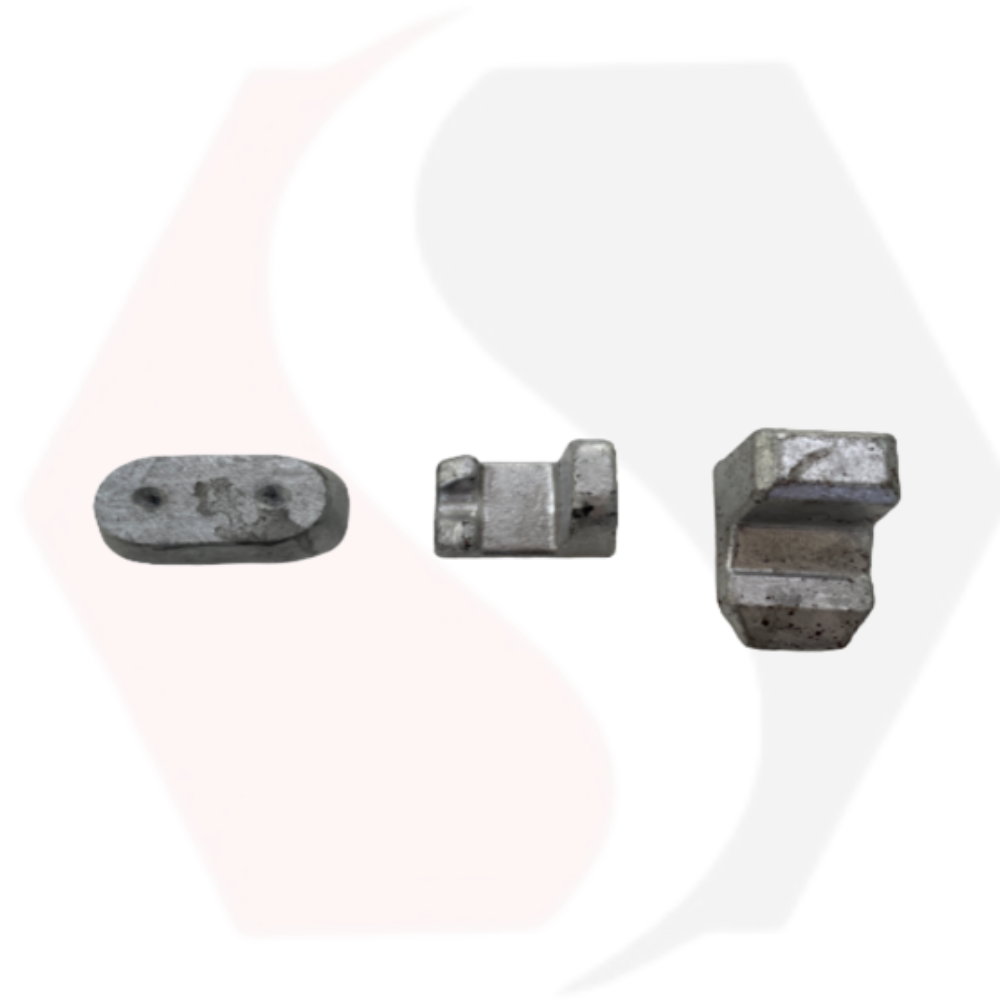

Our heavy steel forging products are precision-crafted using premium zinc, undergoing a rigorous hot forging process. This technology enhances the strength and integrity of each piece, ensuring it can withstand intensive operational demands, especially in automotive settings.

Wide Range of Automotive Applications

Specially designed for the auto parts sector, our forged steel components provide reliable performance in vehicles. Their superior mechanical attributes make them suitable for use in engines, transmissions, suspension systems, and other critical areas requiring strength and endurance.

FAQs of Heavy Steel Forging:

Q: How is heavy steel forging with zinc utilized in auto parts manufacturing?

A: Heavy steel forging with zinc is used to craft auto parts that require exceptional strength and wear resistance. The process ensures superior durability and dimensional accuracy, making these components ideal for critical automotive applications like engine or transmission components.Q: What benefits does the hot forging process offer over other forging methods?

A: The hot forging process significantly improves the grain structure of zinc, enhancing its strength and toughness. This results in auto parts that are more durable and reliable compared to those made through cold forging or casting technologies.Q: When should I choose hot-forged zinc auto parts for my application?

A: You should consider hot-forged zinc auto parts when your application demands high strength, durability, and resistance to environmental wear. They are particularly suitable for high-stress areas within vehicles, ensuring reliable and long-lasting performance.Q: Where are these heavy steel forging parts manufactured and supplied?

A: These heavy steel forged components are manufactured and supplied by a trusted company based in India, serving automotive manufacturers, suppliers, and wholesalers both domestically and internationally.Q: What is the typical process involved in manufacturing these forged auto parts?

A: The manufacturing process involves heating zinc material, shaping it using heavy steel dies under high pressure, and then finishing it with precision techniques. This ensures each forged part meets stringent quality and performance standards required for automotive use.Q: How are these auto parts used in the automotive industry?

A: These forged parts are utilized in various automotive systems, such as engine assemblies, suspensions, and drivetrains. Their robust construction provides the necessary strength and reliability in demanding operational environments.Q: What are the main advantages of choosing a reputable manufacturer and supplier from India for heavy steel forgings?

A: Selecting a reputable Indian manufacturer ensures access to quality products produced with advanced technologies, competitive pricing, and consistent supply chainsmaking it easier for businesses to meet industry demands efficiently.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

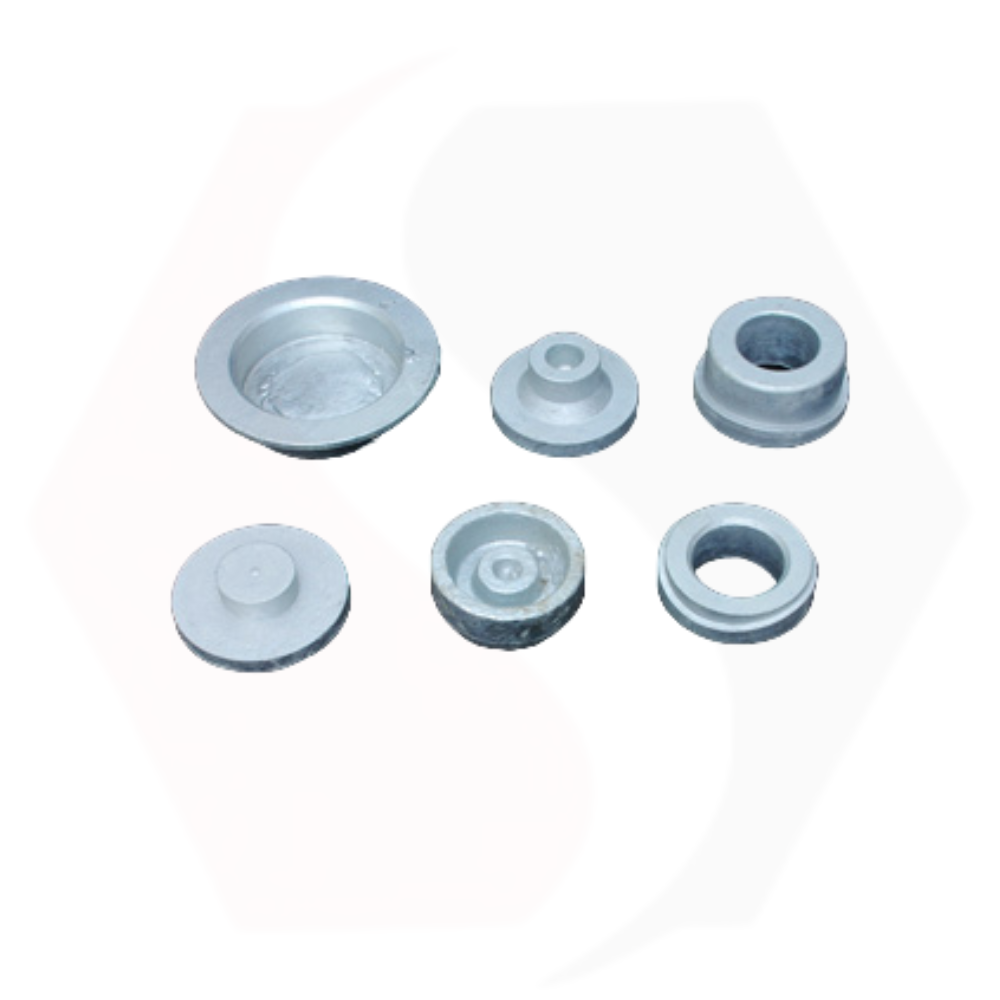

More Products in Forged Automobile Product Category

Forged Automobile Products

Price 35 INR / Piece

Minimum Order Quantity : 5000 Pieces

Product Type : Forged Products

Process : Forging

Material : Steel

Technology : Forging

Ms Forging Metal Components

Price 25 INR / Piece

Minimum Order Quantity : 500 Pieces

Product Type : Forged Products

Process : Hot Forging

Material : Zinc

Technology : Forging

Automobile Components

Price 25.00 INR / Piece

Minimum Order Quantity : 50000 Pieces

Product Type : Forged Products

Process : Hot Forging

Material : Steel

Automobile Parts

Price 20 INR / Piece

Minimum Order Quantity : 5000 Pieces

Product Type : Forged Products

Technology : Forging

Send Inquiry

Send Inquiry