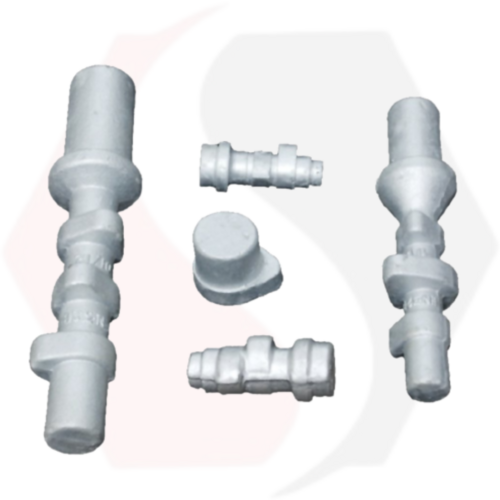

Mining Equipment Forgings

Price 60 INR/ Piece

Mining Equipment Forgings Specification

- Process

- Hot Forging

- Product Type

- Forged Products

- Material

- Steel

- Technology

- Forging

- Application

- Auto Parts

Mining Equipment Forgings Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001

About Mining Equipment Forgings

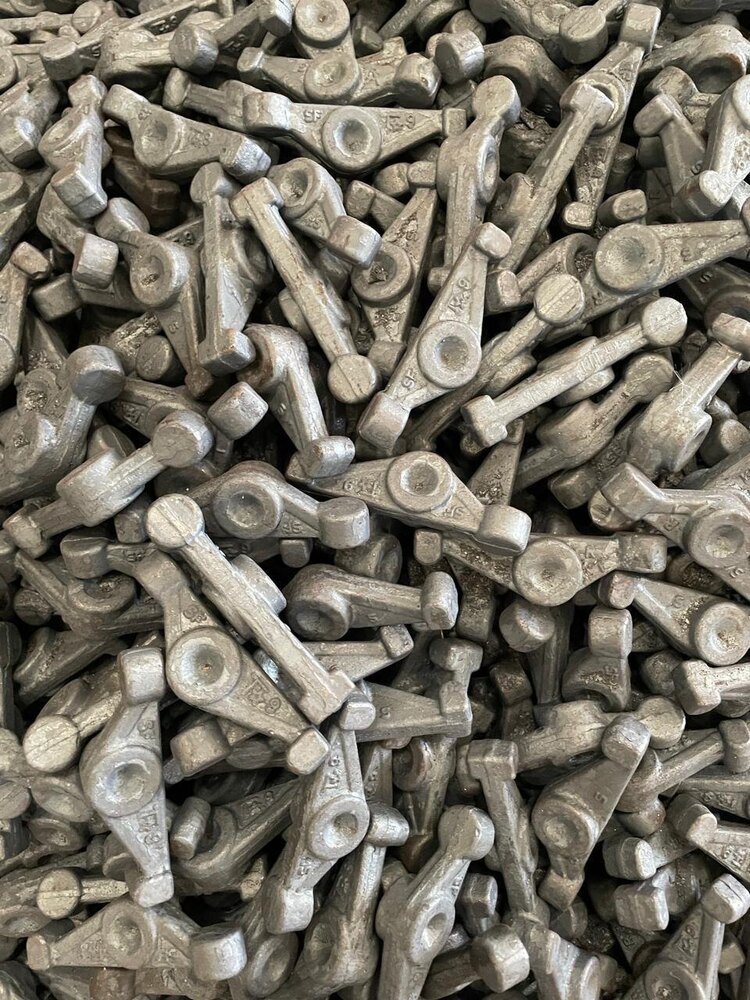

Mining equipment forgings are critical, high-performance metal components engineered to meet the demanding requirements of modern mining operations. Produced through open-die, closed-die, or ring-rolling forging processes, these parts offer superior mechanical strength, toughness, and fatigue resistance compared to cast or machined alternatives. Forging refines the grain structure of the metal, resulting in components that can withstand heavy shock loads, extreme abrasion, and continuous operation in harsh underground or surface mining environments.

These forgings are essential for major mining machinery, including excavators, hydraulic shovels, drills, draglines, crushers, conveyors, and haul trucks. Commonly forged parts include shafts, gears, flanges, links, crusher components, drill rods, track components, and custom wear-resistant parts. Materials often used in mining equipment forgings include alloy steels, carbon steels, stainless steels, and special heat-treated grades designed for maximum durability.

Mining equipment forgings support operational reliability by reducing equipment downtime, minimizing failure risks, and extending maintenance cycles. Their precision and strength make them ideal for high-impact, high-torque applications where safety and long service life are paramount. Overall, these forgings play an essential role in enhancing productivity, efficiency, and safety across the global mining industry.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Forgings Category

Forging Precision Component

Price 40 INR / Piece

Minimum Order Quantity : 5000 Pieces

Material : Other

Technology : Forging

Application : Other

Product Type : Forged Products

Alloy Steel Forgings

Price 20 INR / Piece

Minimum Order Quantity : 5000 Pieces

Material : Zinc

Technology : Forging

Application : Auto Parts

Product Type : Forged Products

Forged Hardware Part

Price 25 INR / Piece

Minimum Order Quantity : 5000 Pieces

Material : Other

Technology : Forging

Application : Other

Product Type : Forged Products

Forging Turbine Hubs

Price 120 INR / Piece

Minimum Order Quantity : 5000 Pieces

Material : Other

Technology : Forging

Application : Other

Product Type : Forged Products

Send Inquiry

Send Inquiry